TM 5-3805-258-24-1

A I R S Y S T E M A N D B R A K E S

3. Push and hold either brake pedal in a down

position.

4. Put soapy water on all connections and valves in

the air circuit. Check for leakage.

NOTE: If air pressure in the reservior gets below

cutin pressure (see chart), start and run the engine

until the air pressure goes up to the cutout pressure.

5.

6.

7.

8.

Release the brake pedal.

Put soapy water on the exhaust diaphragm of

each brake control valve. Check for leakage.

Correct any leakage that is found.

Remove the gauge.

NOTE: During the time the valve are checked for

leakage, check the exhaust passages for restriction,

like mud or dirt. A restriction in an exhaust passage

will prevent or slow the release of pressure air

during normal operation.

AIR COMPRESSOR GOVERNOR

T o o l s N e e d e d : 0 t o 1 3 8 0 k P a ( 0 t o 2 0 0 p s i ) G a u g e .

WARNING

Make reference to WARNING on first page of

AIR SYSTEM AND BRAKES TESTING AND AD-

3.

4.

5.

6.

7.

8.

JUSTING section.

9.

1.

2.

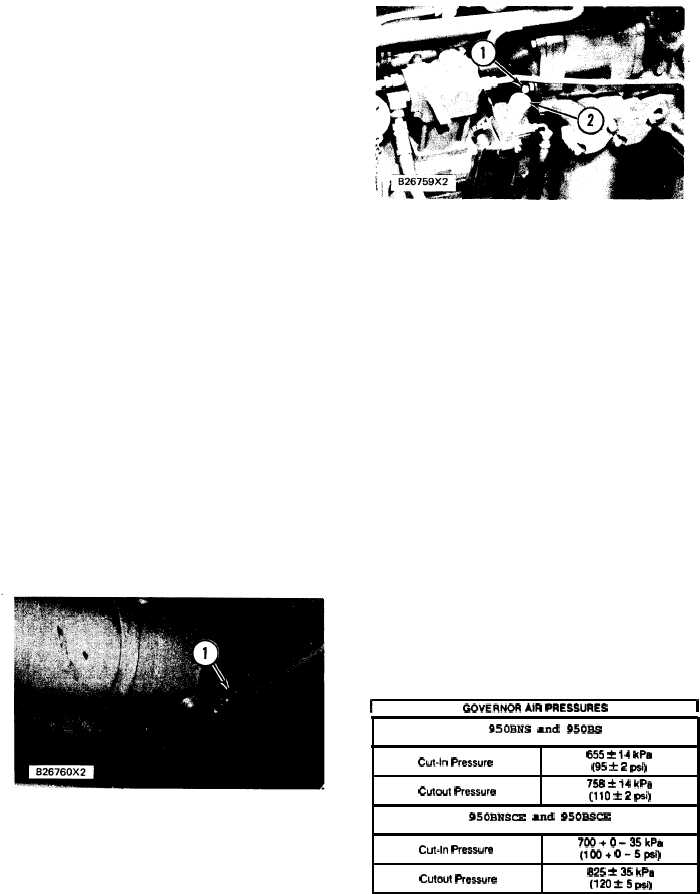

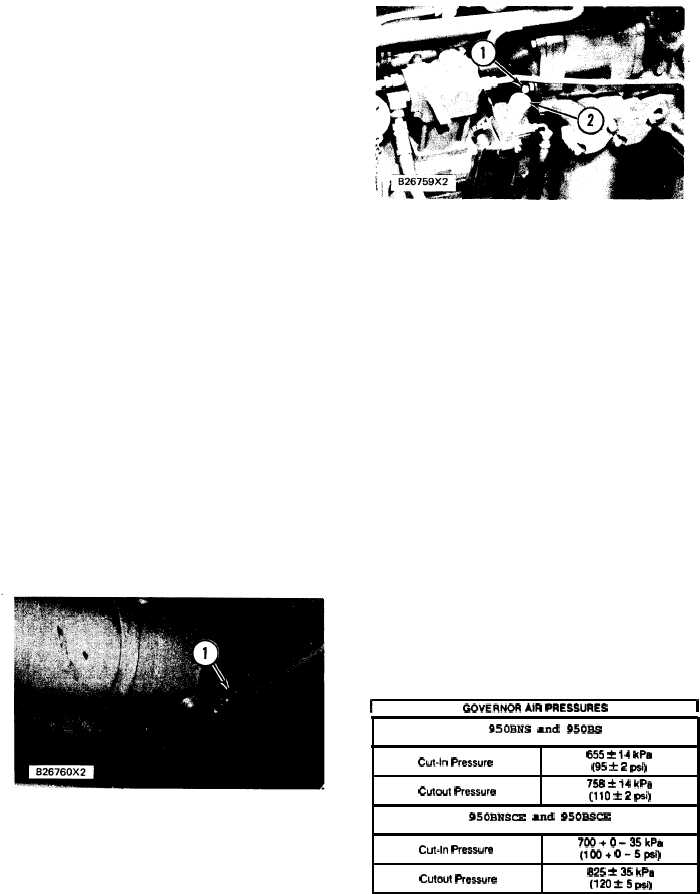

L O C A T I O N T O I N S T A L L G A U GE

1. Drain valve of the air reservoir.

Install a 0 to 1380 kPa (0 to 200 psi) gauge on

drain valve (1) of the air reservoir.

Start the engine and let the pressure go up to the

cutout pressure.

T E S T I N G A N D A D J U S T I NG

A I R C O M P R E S S O R G O V E R N OR

1. Adjustment screw. 2. Locknut.

Read the cutout pressure on the gauge.

Push one of the brake pedals rapidly several

times, until air compressor cuts-in (starts).

Read the cut-in pressure on the gauge.

See chart for correct governor pressures. If the

pressures are not correct, adjust the governor.

Use this procedure to adjust the governor:

a. Loosen locknut (2) adjustment screw (1).

b. Turn the adjustment screw counterclockwise

to make the cutout pressure lower (clockwise

to raise). One turn of the screw changes the

pressure 140 kPa (20 psi). The cut-in pressure

will change the same amount.

If the adjustment screw does not change the

cutout cutout pressure, the unloading valves in

the air compressor are not working correctly.

If the cut-in to cutout pressure difference is not

correct, the governor is not working correctly.

10. Remove the gauge.

[

GOVERNOR AIR PRESSURES

I

950BNS 8nd 950Bs

Cut-h Pressure

655 ~ 14 kPa

(95 * 2 psi)

Cutout Pressure

758 k 14 kPa

(110 * 2 psi)

950BNSCE -d 950Bsm

Cut-In Pressure

700+0 -35kPa

(loo+ o-5pei)

Cutout Pressure

825 &35 kPa

(120 *5 Deii

4-60