9 5 0 B S T E E R I N G S Y S T E M

S T E E R I N G C O N T R O L V A L VE

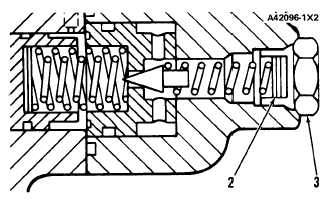

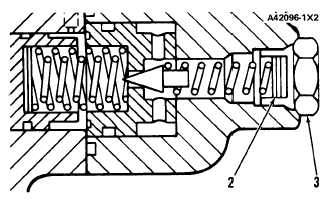

2. Shims. 3. Plug.

If the pressure is not correct:

a. Remove plug (3) from steering control valve.

b. Add shims (2) to increase the pressure setting

and remove shims if a decrease is necessary.

PRESSURE CHANGE FOR ONE SHIM (2)

Part No.

Thickness

Pressure Change

3 H 2 5 4 9

0.25 mm (.010 in.)

3 4 0 k P a ( 5 0 p s i )

STEERING SLIP CHECK

To check the steering wheel slip:

1. Put the machine on a dry hard surface. Raise the

bucket and release the brakes.

2. With the engine at low idle, turn the steering

wheel slowly through one revolution so that there

is a minimum of articulation. Do this in both

directions to get the feel of the steering action.

3. Do this test three more times in each direction.

Make a note of the time required for each of the

revolutions of the steering wheel.

4. Add the three times for each direction. If these

totals are 60 seconds or more, the slip is

acceptable.

5. If the totals are less than 60 seconds, remove the

spool from the steering control valve. Turn the

spool around in its bore (turn end for end). To do

this the spring, retainer and shims must be in-

stalled on the opposite end of the spool. On some

machines this will correct the problem of manu-

facturing tolerances and the slip will then be

TM 5-3805-258-24-1

T E S T I N G A N D A D J U S T I N G

NEUTRALIZER VALVE

L E F T

N E U T R A L I Z E R

V A L VE

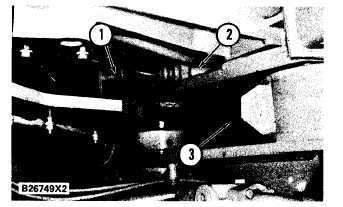

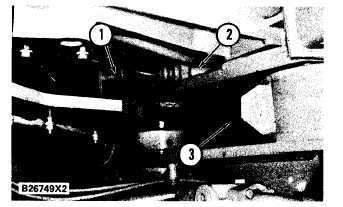

1. Striker. 2. Neutralizer valve. 3. Frame stop (one on each side

o f m a c h i n e ) .

To check the adjustment of striker (1):

1.

2.

3.

4.

5.

Put a 12.7 mm (.50 in.) ball of putty (or similar

material) on both frame stops (3).

Raise an empty bucket about 30 cm (12 in.) and

release the brakes.

With the engine at high idle, steer rapidly into

both stops.

Thickness of the putty must be 9.7 ± 3.7 mm

(.38 ± .12 in.) after the turns. This is the clear-

ance between the frame stops when a full turn

is made.

If the clearance is not correct, adjust the strikers

until the dimension is correct.

acceptable.

4-55