A I R S Y S T E M A N D B R A K E S

TM 5-3805-258-24-1

T E S T I N G

A N D

A D J U S T I N G

AIR SYSTEM AND BRAKES

WARNING

Before making any tests or adjustments on the

brake system, stop the machine on level

ground. Move the control knob for the parking

brake to the ON position. Put blocks in front of

and behind the wheels. Permit only one man on

the machine. Keep all other personnel away

from the machine. Never disconnect any air or

brake fluid lines in the brake system until all

pressure is removed. Failure to remove this

pressure will have a sudden release of air or

brake fluid under high pressure. This can cause

injury to personnel. To remove the pressure

from the brake system: Engage the parking

brake. Stop the engine. Push on either brake

pedal many times until there is no more brake

air pressure. When the pressure has been re-

moved from the air circuit, there will be no

pressure in the brake hydraulic circuit.

NOTE: Before any operation checks are made, open

the drain valve to release any water in the air reser-

voir. Water lowers the capacity in the reservoir and

can cause the air compressor to-run constantly. Close

the drain valve.

VISUAL CHECKS

Before any operation checks are made to the air

system and brakes, visually inspect the complete

system as follows:

1.

2.

3.

4.

Check for cracks or wear in hoses and lines.

Check for restriction of flow; like sharp bends,

clamps that are not installed correctly, and dam-

age to hoses and lines.

Check for loose connections.

Check for damage to components.

AIR RELIEF VALVE

The relief valve opens at 1030 kPa ( 150 psi) and has

no adjustment.

CHECKS FOR LEAKAGE IN AIR CIRCUIT

T o o l s N e e d e d : 0 t o 1 3 8 0 k P a ( 0 t o 2 0 0 p s i ) G a u g e .

WARNING

Make reference to WARNING on first page of

AIR SYSTEM AND BRAKES TESTING AND AD-

JUSTING section.

NOTE: It is possible to hear the sound of air leakage.

Air leakage can be seen when water with soap (soapy

water) is put on the connections, valves and hoses.

L O C A T I O N T O I N S T A L L G A U GE

1. Drain valve for the air reservoir.

1. Install a 0 to 1380 kPa (0 to 200 psi) gauge in

drain valve (1) for the air reservoir.

2. Start the engine and let the air pressure go up to

the cutout pressure. Stop the engine.

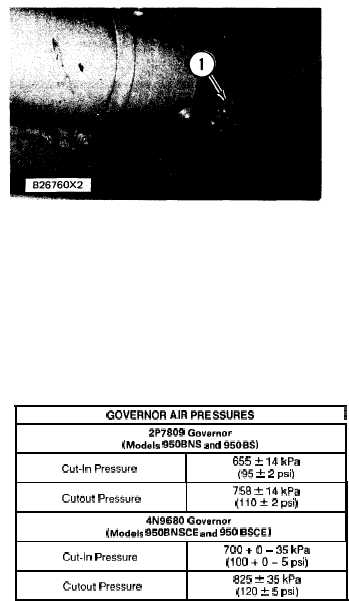

NOTE: See chart for correct governor cutout pressure

If cutout pressure is not correct, see the subject, AIR

COMPRESSOR GOVERNOR.

GOVERNOR AIR PRESSURES

I

2P7809 Govarnor

(Models 950BNS and 950BS)

Cut-In Pressure

655 k 14 kPa

(95 t 2 psi)

Cutout Pressure

758 k 14 kPa

(110&2 psi)

4N9680 Governor

(Medals 950BNSCE and 950 BSCE)

Cut-In Pressure

700 + O – 35 kPa

(100 +0-5 psi)

Cutout Pressure

825 ? 35 kPa

(120 * 5 psi)

4-59