TM 5-3805-258-24-1

9 5 0 B S T E E R I N G S Y S T E M

T E S T I N G

A N D

A D J U S T I N G

3. Shims (2) are available in two thicknesses.

5J4776 Shims are 0.13 mm (.005 in.) thick.

4J8224 Shims are 0.25 mm (.010 in.) thick. Two

4J8224 Shims will change the steering time at

high idle by approximately .1 second.

EXAMPLE: A check of the steering times shows

that the right turn time is .4 second more than the left

turn time. Shims (2) must be added to decrease the

difference between the times. The addition of four

4J8224 Shims will decrease the right turn time by

approximately .2 second and increase the left turn

time approximately .2 second. This will make the

right and left turn times approximately the same.

4. Replace the end cover on the control valve.

the

lets

2.

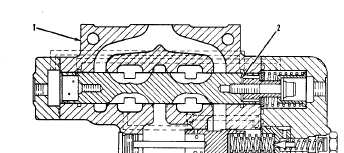

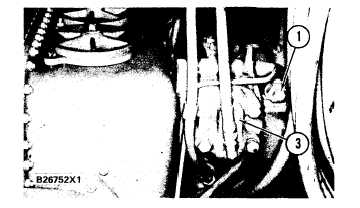

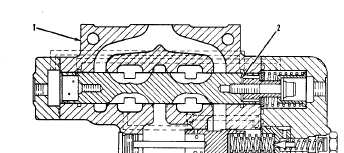

S T E E R I N G C O N T R O L V A L VE

1. Control valve. 2. Flow balance shims. 3. Cylinder flow

s h i m s .

If both steering times (right and left) are slow,

cylinder flow shims (3) must be added.

4J6806 Shim thickness . . . . . . . . . . .

1.22 mm (.048 in.)

One shim will change the steering times at high

idle by approximately .1 second.

PRESSURE TEST OF STEERING SYSTEM

Loosen the filler cap on the tank to permit the

pressure in the tank to go down before installa-

tion or removal of any test equipment.

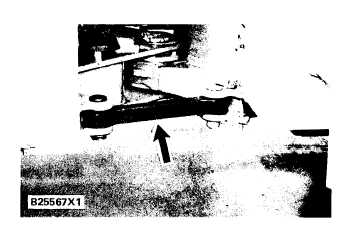

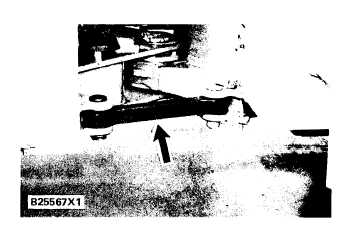

1. Install the anti-pivot link so the machine can

not turn.

A N T I - P I V O T L I N K I N S T A L L ED

NOTE: If the anti-pivot link can not be installed, the

pressure setting can be checked by an adjustment of

striker (stud assembly) that is not correct. This

the front and rear frame stops come in contact.

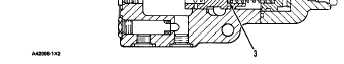

Remove plug (1) and install a 2P1314 Con-

nector where plug (1) was removed. Install the

7S8714 Pressure Gauge (0 to 4000 psi or 0 to

28000 kPa) and the

connector.

6V3081 Hose on the

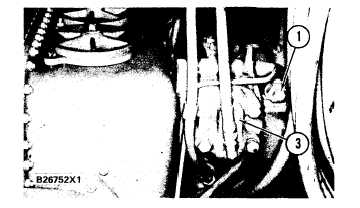

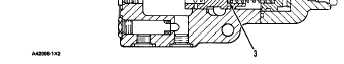

S T E E R I N G C O N T R O L V A L VE

1. Plug. 3. Plug.

Alternate Step 2. Remove plug (1) and perma-

3.

4.

nently install a 6V3965 Valved Nipple where

plug (1) was removed. Connect 6V3081 Hose

to the nipple with a 6V4143 Coupler. Install

the 7S8714 Pressure Gauge.

Start the engine and operate it at high idle.

Turn the steering wheel until the relief valve

opens. Note the indication on the gauge. The

correct relief pressure is 17200 ± 340 kPa

(2500 ± 50 psi).

4-54