TM 5-3805-258-24-2

ENGINE

FUEL INJECTION

DISASSEMBLE FUEL INJECTION

PUMPS

1251-15

start by:

a) remove fuel injection pumps

CAUTION

Be careful when the injection pumps are disas-

sembled. Do not damage the surfaces of the

plungers, barrels and bonnets. Any scratches

will cause leakage inside the fuel injection

pump. The plunger and barrel for each pump

are made as a set. Do not put the plunger of one

pump in the barrel of another pump. If one part

has wear, install a complete new pump assem-

bly. Be careful when the plunger is put into the

bore of the barrel.

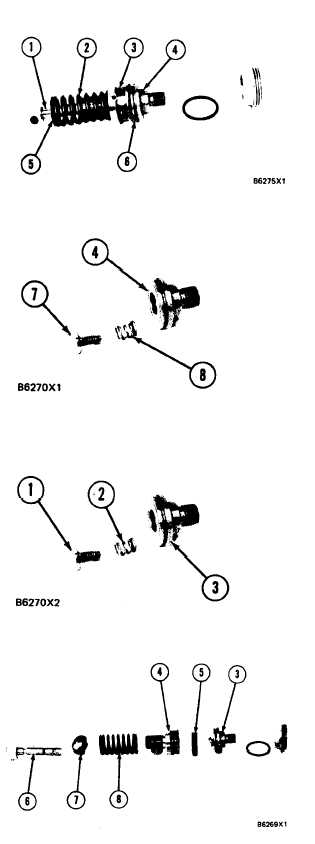

1.

2.

Pull plunger (1) and washer (5) out of barrel (3)

and spring (2).

Remove washer (5) from plunger (l).

CAUTION

Do not remove the gear from the plunger. The

gear and plunger are assembled and adjusted

at the factory.

3.

4.

5.

Remove spring (2) from barrel (3).

Remove ring (6) and make a separation of barrel

(3) and bonnet (4).

Remove check assembly (7) and spring (8) from

bonnet (4). If check assembly (7) is disassem-

bled, do not mix parts with parts from another

check assembly.

ASSEMBLE FUEL INJECTION

PUMPS

1251-16

CAUTION

Put clean fuel oil on all parts during assembly.

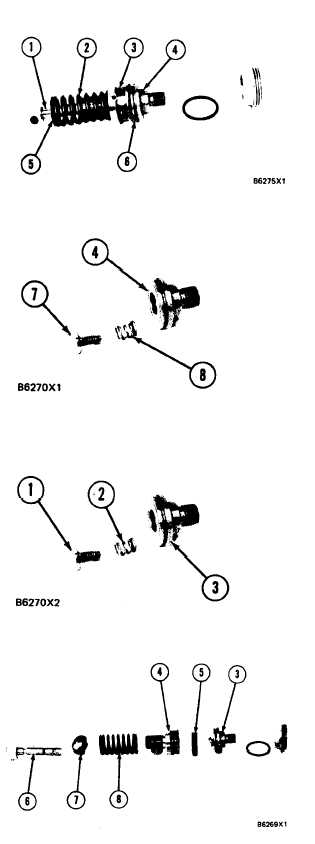

1.

2.

3.

4.

5.

Install spring (2) and check assembly (1) in bon-

net (3).

Install bonnet (3) on barrel (4) and install ring (5)

to hold them together. Do not slide bonnet (3)

across barrel (4) because check assembly (1) in

the bonnet can cause damage to the face of barrel

(4).

Install spring (8) on barrel (4).

Install washer (7) on plunger (6) with the flat side

toward the gear on the plunger.

Install plunger (6) in barrel (4) until washer (7) is

engaged in the spring.

end by:

a) install fuel injection pumps

5-78

DISASSEMBLY AND ASSEMBLY

PUMPS