TM 5-3805-258-24-2

POWER TRAIN

FRONT AND REAR

17.

18.

19.

20.

21.

22.

Heat bearing cone (24) to a maximum temper-

ature of 135°C (275°F). Install bearing (24)

Fasten a hoist to housing (21) with tooling (B).

Put housing (21) in position on the pinion and

bearing.

Heat bearing cone (25) to a maximum temper-

ature of 135° C (275° F) and install it on-the

pinion shaft as shown.

NOTE: Models 950BNSCE and 950BSCE use

a nut and keyed washer rather than two nuts

and a lock.

Install nut (28) on the pinion shaft and put oil

on bearings. While the pinion is slowly turned,

tighten nut (28) with tool (E) until the torque

needed to turn the pinion is 0.9 ± 0.2 N-m (8 ±

2 lb.in. for new bearings).

If original bearings are used, tighten nut

until torque to turn pinion is 0.5 ± 0.2 N-m (4

± 2 lb.in.). Put clean oil on lock (27) and install

it on the pinion shaft. Install nut (26) with tool

(E) on the pinion shaft. Bend the tab of the

lock in the groove of nut (26). On models

950BNSCE and 950BSCE peen nut collar into

key into key slot of shaft. Check the torque

needed to turn the pinion. The torque still

must be 2.0 ± 0.2 N-m (18 ± 2 lb.in.) for new

bearings and 0.5 ± 0.2 N-m (4 ± 2 lb.in.) for

used bearings. If the torque is not correct, an

adjustment must be made to nut (28).

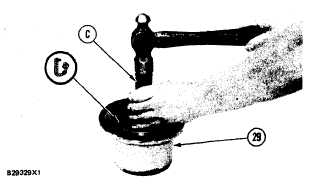

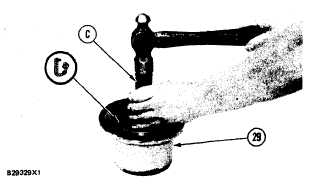

Use tool group (C) and install the seal in re-

tainer (29). Make sure the lip of the seal is

toward the inside of retainer (29) as shown. Put

clean oil on the lip of the seal after installation.

DISASSEMBLY AND ASSEMBLY

DIFFERENTIALS

5-206