TM 5-3805-258-24-2

ENGINE

DISASSEMBLY AND ASSEMBLY

AIR COMPRESSOR CRANKSHAFT

Models 950BNS and 950BS

REMOVE CRANKSHAFT

11–1065

start by:

a) remove head assembly

b) remove piston and rod

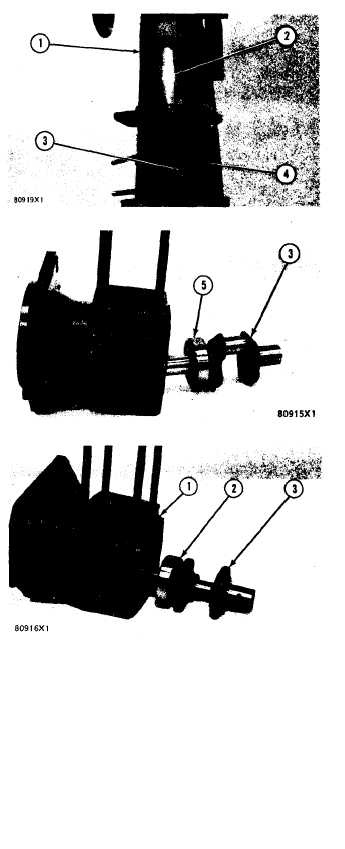

1. A press (1) can be used to remove crank-

shaft (3) from crankcase (4).

2. Put a pipe (2), with a bore larger than 1.03

in. (26.2 mm) and a diameter of approxi-

mately 2 in. (50.8 mm) with an approxi-

mate length of 6 in. (152.4 mm), over the

end of crankshaft (3) and on bearing (5).

3. Push crankshaft (3) and bearing (5) out of

crankcase (4) as a unit.

4. Remove bearing (5).

INSTALL CRANKSHAFT

12–1065

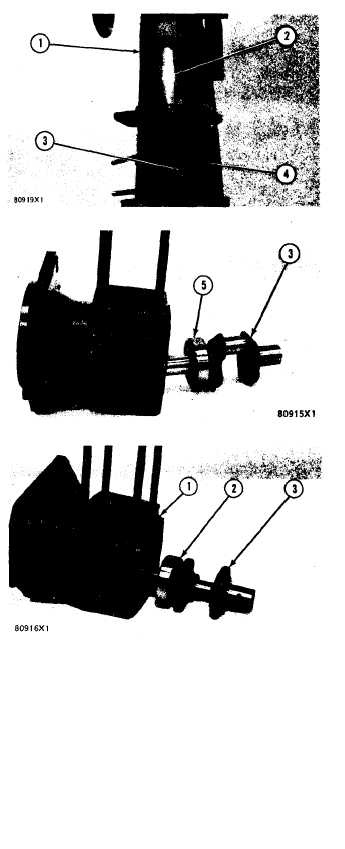

1. Heat the crankshaft ball bearing in oil to a

temperature of not over 350°F (175°C) and

put the bearing on crankshaft (3).

2. Put the bearing and crankshaft (3) into

crankcase (1) with the crankcase resting on

the large flange end.

3. Outer race (2) of the

the crankcase with a

many locations on

bearing is pushed into

soft metal rod put at

outer race (2) while

hitting the rod with a hammer.

end by:

a) installing piston and rod

b) installing head assembly

5-18