ENGINE

PISTON AND ROD

PISTON AND ROD REMOVAL

1.

2.

3.

4.

5.

6.

7.

8.

start by:

a) remove head assembly

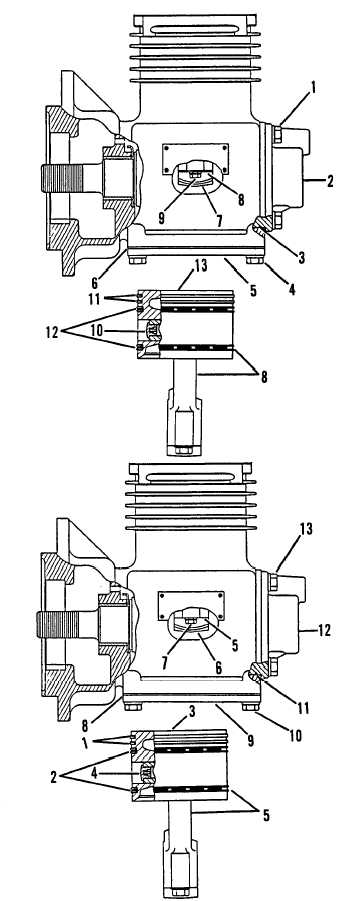

Remove four bolts and lockwashers (1).

Remove cover (2) and seal (3).

Remove four bolts and lockwashers (4).

Remove cover (5) and gasket (6).

Put matching identification marks on the

rod cap (7) and piston rod (8) to ensure

correct assembly.

Remove bolts (9) and rod cap (7), then

remove piston and rod (8) from the crank-

case.

Put matching identification marks on the

piston and the rod to ensure correct assem-

bly.

Remove retaining ring from wrist pin (10)

and push pin from piston and rod.

Clean all parts.

Remove piston rings (11) and oil rings (12).

Clean ring grooves in piston (13) with a piece

of hard wood.

INSTALL PISTON AND ROD

1.

2.

3.

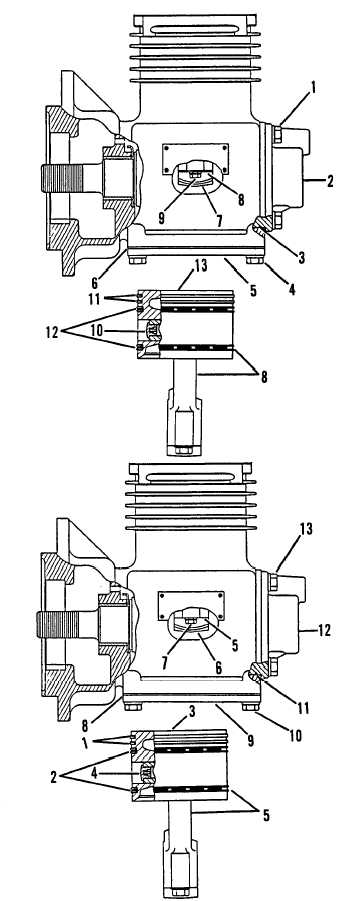

Inspect piston for scoring, cracks, or en-

larged ring grooves. Replace piston if any of

these conditions exist.

Check wrist pin installation. If pin can be

inserted through the piston and rod with

only slight pressure, fit is acceptable, If pin

is a loose fit, the piston and rod assembly

must be replaced.

Install piston rings (1) and oil rings (2). The

gap for each ring must not be near the piston

pin bore, and each gap must be approxi-

mately 1200 from the gap in the next ring.

TM 5-3805-258-24-2

DISASSEMBLY AND ASSEMBLY

5-18d