ENGINE

TM 5-3805-258-24-2

4.

5.

6.

7.

8.

9.

10.

11.

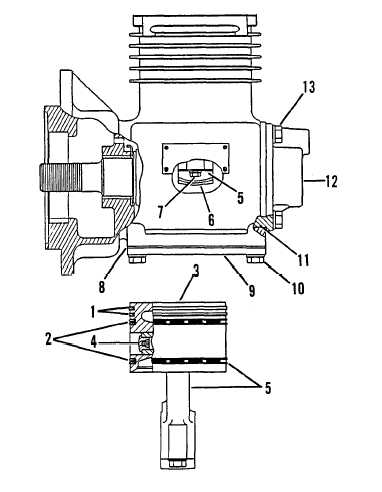

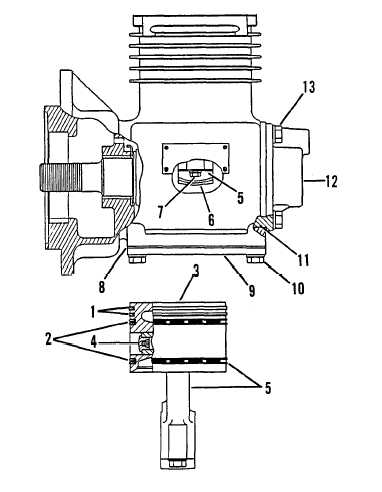

PISTON

Measure clearance between grooves and

piston rings (1), and between grooves and oil

rings (2). Clearance must be 0.004 to 0.012

in. (0.10 to 0.30 mm).

Assemble piston (3) to rod. Be sure identifi-

cation matching marks made during disas-

sembly are aligned.

Install wrist pin (4) and secure in place with

retaining ring.

Install rod and piston (5) in crankcase.

Measure piston and oil ring gaps with piston

and rod (5) installed in cylinder bore.

Piston Ring Gap Clearance: 0.002 to 0.004

in. (0.05 to 0.010 mm).

Oil Ring Gap Clearance: 0.0015 to 0.0035

in. (0.04 to 0.09 mm).

Align matching marks of rod cap (6) and

piston rod (5). Install rod cap (6) and bolts

(7).

Install new gasket (8). Install cover (9), and

bolts and lockwashers (10).

Install new seal (11), cover (12), and bolts

and lockwashers (13).

end by:

a) install head assembly

DISASSEMBLY AND ASSEMBLY

AND ROD

5-18e