TM 5-3802-262-10

3-8. SERVICING (CONT)

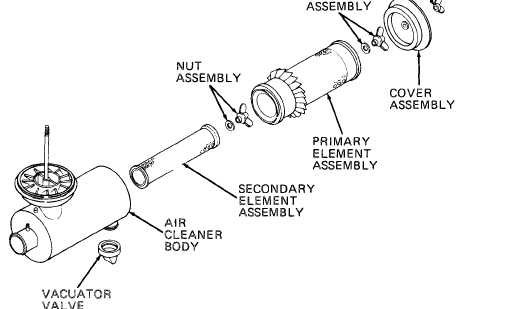

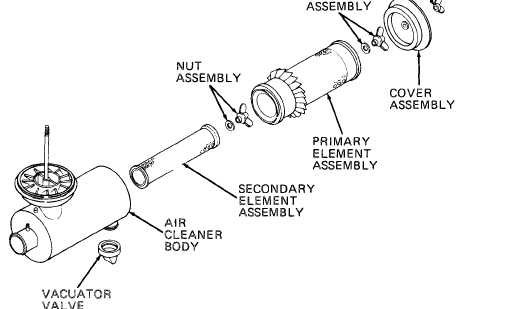

a. Air Cleaner (Cont).

Grasp vacuator valve and pull off air cleaner body. Dump any dust or

dirt in vacuator valve.

Don’t use compressed air to dry primary element assembly. To do so may

cause damage to primary element assembly.

Don't clean secondary element assembly. Secondary element assembly shall

be replaced every third servicing of primary element assembly, when

secondary element assembly is more than two years old (date of manufac-

ture is stamped on top of secondary element assembly), when it is dam-

aged, or when red band in restriction indicator stays in view after pri-

mary element assembly has been cleaned or replaced.

(g)

Wash primary element assembly using general purpose detergent. Allow

primary element assembly to air dry.

(h)

Check for holes in primary element assembly. Check if metal covering

is bent. If holes in element are apparent or if metal covering is

bent, install new primary element assembly.

NOTE

Clean primary element assembly using compressed air not exceeding 30

psi.

Inspect new primary element assembly as described in step (2)(h) above;

if new primary element assembly is damaged, replace it.

3-41