TM 5-3805-262-10

2-17. OPERATING PROCEDURES (CONT)

d. Operating the Loader (Cont).

(5) Truck Loading.

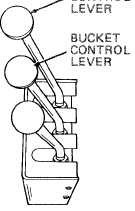

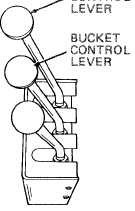

(a) Use LIFT ARM control lever in

RAISE to raise bucket. Move

loader toward side of truck.

(b) Use brake treadle valve to slow loader and declutch

treadle valve to stop loader.

(c) As you move load toward truck, use bucket height

control to automatically position bucket at desired

dump height.

(d) Dump load into truck by using BUCKET control lever in

DUMP .

(e) Use return-to-dig to position bucket for next cycle. Do this by using

LIFT ARM control lever in FLOAT and BUCKET control lever in CROWD.

Bucket will automatically rollback and lower to ground.

(f) After bucket is on ground, return LIFT ARM control lever to NEUT.

2-18. PREPARATION FOR MOVEMENT

a. Driving.

The loader may be moved under its own power without any special pre-

paration or may be transported on a suitable truck and flatbed trailer. If trans-

ported on a flatbed trailer:

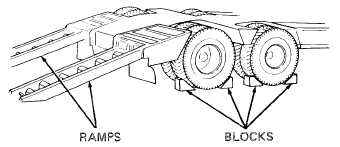

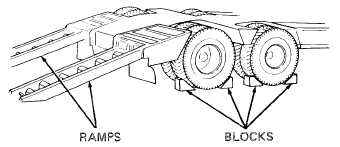

(1) Place blocks at front and rear

of each trailer wheel.

Be sure ramp is securely

fastened to flat bed trailer

to prevent personnel injury

and damage to equipment.

(2) Place ramps between flat bed

trailer and ground.

Before moving loader up ramps, remove all ice, oil or grease from ramp

to prevent loader from falling and causing death or serious injury and

extensive damage to loader. Tell personnel to move away from loader.

NOTE

Ramps shall not provide a grade of more than 40 percent.

2-57