TM 5-3805-262-10

2-17. OPERATING PROCEDURES (CONT)

d. Operating the Loader (Cont).

(b)

(c)

(d)

(e)

(2)

(a)

(b)

(c)

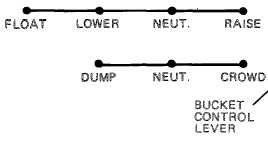

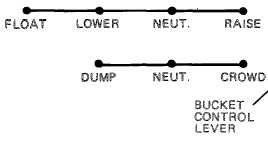

Use BUCKET control lever in

DUMP position to adjust po-

sition of bucket so that

bucket front edge is lower

than rear of bucket. Bucket

teeth will help you dig in

this type of operation.

Move loader into area to be excavated with transmis-

sion in low range forward and engine speed at full

throttle.

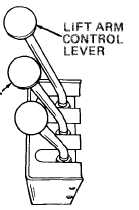

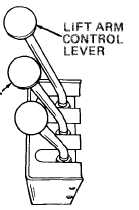

Use LIFT ARM control lever to lower bucket to ground. When bucket is at

desired depth, move LIFT ARM control lever to NEUT. position and contin-

ue to move loader forward.

When bucket is full, use BUCKET control lever in CROWD position to roll

bucket back and fill it with excavated material. You lose time when ma-

terial is pushed in front of bucket.

Loading Loose Material.

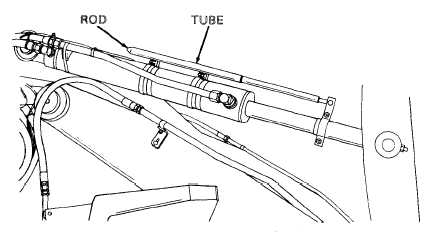

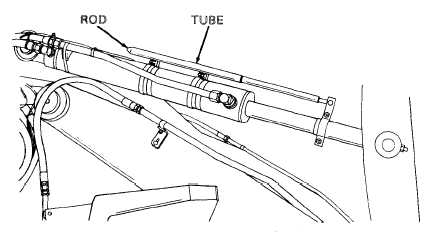

Use bucket level indicator to ensure that bottom of bucket is level with

ground. When end of rod is one inch out of tube, bottom of loader bucket

is level with ground.

Put LIFT ARM control lever in FLOAT and move loader into material.

When speed of loader starts to decrease, press declutch treadle valve

and accelerator pedal, put LIFT ARM and BUCKET control levers in RAISE

and CROWD positions, respectively, to raise and rollback loader bucket.

2-55