TM 5-3805-262-20

12-1. SIGNALING DEVICES MAINTENANCE (CONT)

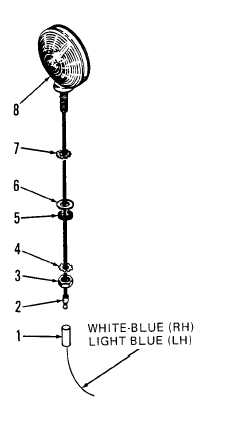

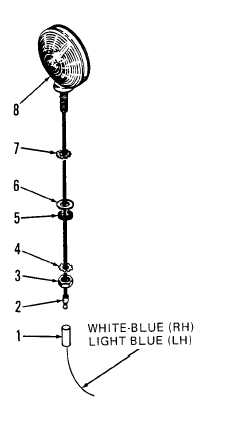

e. Turn Signal Lamp Assemblies (cont).

INSTALLATION

(1)

(2)

(3)

( 4 )

(5)

(6)

Inspect lamp assembly (8) wire for cracked

or broken insulation or broken wire strands

at connection to terminal (2). Repair crack-

ed or broken insulation by applying insula-

tion tape to area. If broken wire strands

are seen, cut wire as close to terminal as

possible. Strip 1/4 inch insulation from end

of wire taking care not to cut through wire

then crimp new terminal securely onto wire.

Inspect wiring harness terminal (1) wire for

cracked or broken insulation or broken wire

strands at connection to terminal. Repair

cracked or broken insulation by applying in-

s u l a t i o n t a p e t o a r e a.

If broken wire strands

are seen, cut wire as close to terminal as

possible. Strip 1/4 inch insulation from end

of wire taking care not to cut through wire

then crimp new terminal securely onto wire.

Install lock washer (7), washer (6), and

rubber washer (5) on lamp assembly (8)

mounting stud.

position lamp assembly (8) mounting stud

with installed parts in mounting hole at

top of cab.

From inside cab,

install and tighten lock washer (4) and nut (3).

Connect terminals (1 and 2) by grasping both with your fingers, alining,

and firmly pushing them together.

NOTE

Repeat steps (1) through (6) above to install remaining lamp assembly

( 8 ).

(7) Start engine and operate at idle speed. Move turn signal switch lever to

up position and check that left lamp assembly blinks on and off. Move

lever to down position and check that right lamp assembly blinks on and

off. Move lever to center position and turn off engine. If lamps do not

operate, refer to troubleshooting (page 3-198).

(8) Glue cab foam to cab ceiling using small amount of adhesive applied to

back of foam.

12-18