TM 5-3805-262-20

REMOVAL (SHEET 2 OF 3)

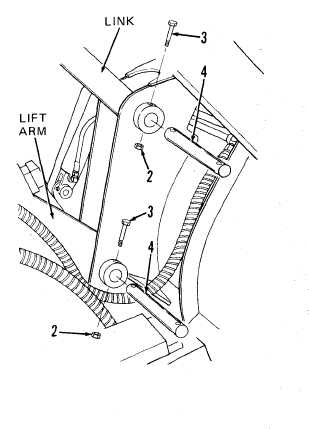

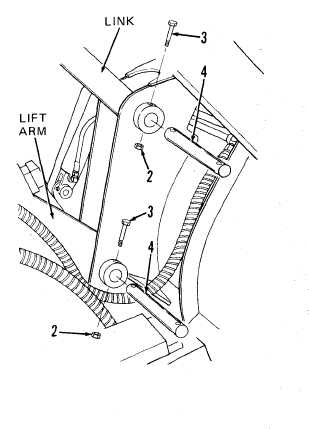

(2) At top of loader bucket assembly where link is secured to loader bucket

assembly, remove lock nut (2) and capscrew (3).

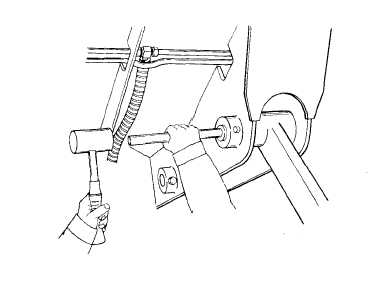

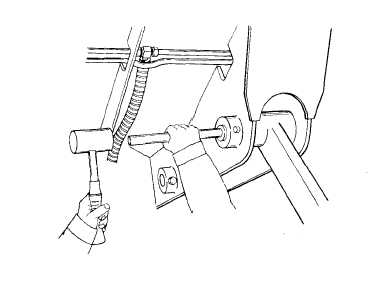

( 3 ) P r e s s p i v o t p i n ( 4 ) f r o m b u c k et

using 1-7/8 inches diameter rod

and hammer as shown.

( 4 ) R e p e a t s t e p s ( 2 ) a n d ( 3 ) a b o v e to

remove lock nut (2), capscrew (3),

and pivot pin (4) securing lift arm

to loader bucket assembly.

(5) Repeat steps (1) through (4) to disconnect link and lift arm from remain-

ing side of loader bucket assembly.

I n f o l l o w i n g s t e p , d o n ’ t a l l o w l i n k s t o s t r i k e p o l i s h e d s u r f a c e o f t i l t

c y l i n d e r a s s e m b l i e s r o d .

T o d o s o m a y c a u s e d a m a g e t o c y l i n d e r

assemblies resulting in hydraulic oil leakage and requiring replacement

and repair of cylinder assemblies .

(6) Swing links up and over bellcrank assemblies and secure in position so

that they cannot move. Make sure that links don't strike and damage po-

l i s h e d s u r f a c e o f t i l t c y l i n d e r a s s e m b l i e s r o d.

12-21