TM 5-3805-262-20

12-2. BUCKET LIFT ARMS AND PIVOT ASSEMBLIES MAINTENANCE

This procedure covers visual inspection of lift arms and pivot assemblies. No tools

or parts/materials are required to perform this procedure.

a .

b .

c .

d .

e .

f .

g .

NOTE

Notify direct support maintenance

i f a n y a b n o r m a l c o n d i t i o n s a re

s e e n d u r i n g p e r f o r m a n c e o f

following procedures.

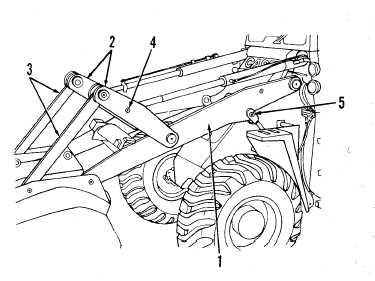

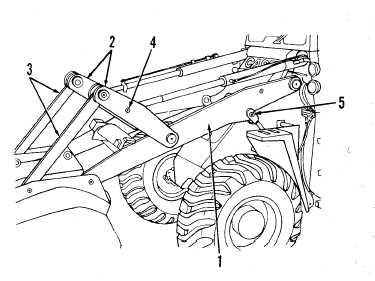

A t e i t h e r l e f t o r r i g h t s i d e of

loader, check lift arm (1) for

c r a c k s , breaks, or other damage.

Check bellcrank assembly (2) for

cracks, breaks, broken welds, or

other damage.

Check link (3) for cracks,

b r e a k s,

or other damage.

Check lift and tilt cylinder assemblies rod end mountings (4 and 5) for loose

or missing mounting hardware. If hardware is loose, tighten; install if miss-

i n g .

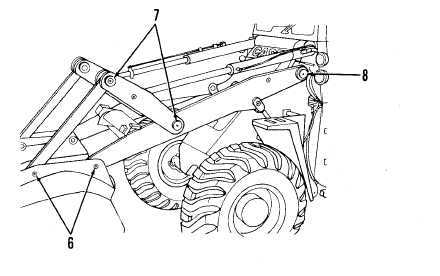

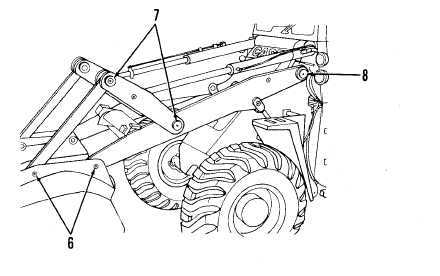

Check bucket pivot pin points (6) for loose or missing hardware. If hardware

i s l o o s e , t i g h t e n ; i n s t a l l i f m i s s i n g .

Check bellcrank pivot pin points (7) for loose or missing hardware.

Check lift arm pivot pin points (8) inside cab for damaged or missing retain-

i n g r i n g , b e n t s h a f t,

or damaged shaft head (on side of lift arm at attachment

t o f r o n t c h a s s i s ).

12-19