TM 5-3805-262-20

3-25. HYDRAULIC SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

(ALL OTHER CYLINDERS

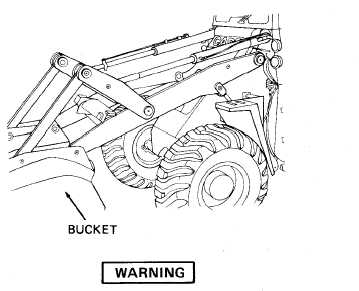

3 . BUCKET TILT CYLINDER ASSEMBLIES OPERATION SLUGGISH OR POOR

OPERATE PROPERLY) (Cont).

S t e p 4 . ( C o n t ).

Hydraulic system pressure is over 2000 psi a n d h y d r a u l i c r e s e r v o i r i s

p r e s s u r i z e d w i t h c o m p r e s s e d a i r. Before loosening or disconnecting any

h y d r a u l i c h o s e s , l i n e s , o r f i t t i n g s , l o o s e n h y d r a u l i c r e s e r v o i r f i l l

c a p , a n d o p e r a t e a l l h y d r a u l i c c o n t r o l l e v e r s t o r e l i e v e h y d r a u l i c

system pressure. Failure to do so could cause serious injury or death.

If you are injured obtain medical assistance immediately.

Disconnect hose connected to rod end of each bucket tilt cylinder

assembly from tube that comes through side of loader front chassis.

Install a cap on each tube.

S t a r t e n g i n e a n d o p e r a t e a t f u l l t h r o t t l e.

Hold BUCKET control lever in DUMP position and tell assistant to

check for hydraulic oil leakage at each hose disconnected above.

a. If there is constant leakage from a hose, the cylinder packing

is damaged. Shut off engine and replace bucket tilt cylinder

assembly connected to hose which was constantly leaking (page

1 1 - 4 ).

b. If there wasn’t constant leakage from a hose, notify next higher

maintenance level (additional checks must be performed).

3-181