TM 5-3805-262-34

CLEANING AND INSPECTION (SHEET 2 OF 2)

e.

f.

g.

h.

i.

j.

Dry cleaning solvent P-D-680 used to clean

Wear protective goggles and gloves and

parts is toxic and flammable.

use only in a well ventilated

area. Avoid contact with skin, eyes and clothes and don-t breathe

vapors. Do not use near open flame or excessive heat and don’t smoke

when using it. Failure to do so could cause serious injury. If you be-

come dizzy while using cleaning solvent, get fresh air and medical

attention immediately. If contact with skin or clothes is made, flush

with large amounts of water. If contact with eyes is made, wash eyes

with water and get medical aid immediately.

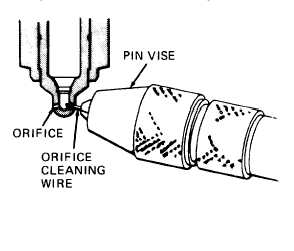

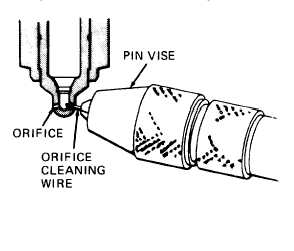

Using a stone, remove sharp edges from end

of cleaning wire. A small flat on one side

of cleaning wire will make it easier to cut

carbon from orifice. Put cleaning wire in

spray orifice and turn wire until it is

free. Wash nozzle tip using cleaning sol-

vent P-D-680 and inspect tip using a

magnifying glass. Replace nozzle tip and

valve as an assembly if orifice in tip

shows damage at edges. Damage to orifice

will change spray pattern.

Compressed air used for cleaning purposes will not exceed 30 psi. Use

only with effective chip guarding and personal protective equipment

(goggles/shield, gloves, etc). Failure to do so could cause serious

injury to eyes and possible blindness. If you hurt your eyes or if a

foreign object is blown into your eyes, seek medical attention

immediately.

Using compressed air, clean all channels of nozzle tip. Apply compressed air

at both ends of nozzle tip to remove all carbon deposits.

Carefully clean inside diameter of nozzle tip to remove all dirt, varnish, and

other deposits. If necessary, use paint thinner to remove varnish deposits.

Use compressed air to remove foreign matter.

Using a brass wire brush, remove deposits from seat location of nozzle valve.

If necessary, use paint thinner and a cleaning pad made of felt to remove

varnish. Check valve for pitting or damage which could cause leakage.

Install nozzle valve in nozzle tip and ensure that it slides freely in nozzle

tip.

Use spring gage to check adjusting spring compression under load. Replace

adjusting spring if pressure required to compress spring to 1.00 inch is not

87.5 pounds.

4-83