TM 5-3805-262-34

4-2. FUEL INJECTORS MAINTENANCE (CONT)

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

1.

m.

n.

Clean all parts using clean diesel fuel.

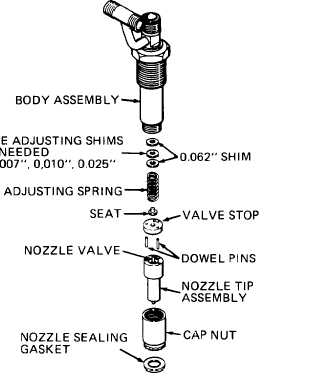

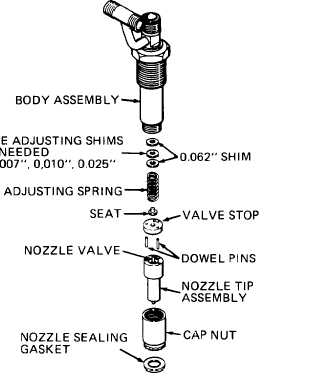

Install a 0.062 inch thick shim in nozzle body.

Install pressure adjusting shims removed

during disassembly.

NOTE

Pressure adjusting shims must

always be between 0.062 inch

thick shims.

Install a 0.062 inch thick shim over

pressure adjusting shims.

Install adjusting spring in body assembly.

Install seat, small diameter end of seat

toward adjusting spring.

Install valve stop, alining valve stop dowel

pins with dowel pin holes in body assembly.

Install nozzle valve in nozzle tip and slide

nozzle valve up and down several times to

ensure that it moves freely.

Aline dowel pin holes in nozzle tip assembly with dowel pins in valve stop.

Install nozzle tip assembly in valve stop.

Apply oil-soluble grease to nozzle tip assembly shoulder. Don-t put grease on

body assembly or cap nut threads.

Install cap nut over end of nozzle tip assembly and turn cap nut two or three

turns.

Put a 3/8 inch open end wrench, to be used as a holding fixture, in a vise.

Position body assembly in open end wrench.

Using torque wrench and socket, tighten cap nut to 30 to 35 lb-ft.

Adjust fuel injector opening pressure (page 4-85).

4-84