TM 5-3805-262-34

4-3. TRANSMISSION MAINTENANCE (CONT)

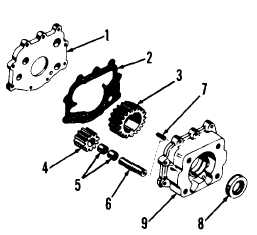

j. Charging Pump (Cont).

INSPECTION AND REPAIR

(1)

(2)

(3)

(4)

(5)

(6)

Inspect cover (1) for cracks, breaks, or deformation. Replace as neces-

sary.

Inspect gears (3 and 4) for nicked, burred, or broken teeth or stripped,

twisted, or chipped splines. If gears require replacement, replace charg-

ing pump as an assembly.

Inspect shaft (6) for cracks, bent condition, deformation, or wear in any

one area. If any of above conditions are seen, replace charging pump as a

complete assembly.

Inspect pump housing (9) for cracks, breaks, deformation, or other dam-

age. If any of above conditions are seen, replace charging pump as a com-

plete assembly.

Inspect bearings (5) for roughness of rotation, chipped or cracked races,

or excessive wear. If bearings require replacement, go to step (6) below

otherwise go to reassembly.

Using 7/8 inch outside diameter sleeve and hydraulic press, press bear-

ings (5) from driven gear (4). Discard bearings. Press new bearings into

driven gear until end of each bearing is even with outside edge of driven

gear.

LEGEND

1. Cover

2. Gasket

3. Drive gear

4. Driven gear

5. Bearings (2)

6. Shaft

7. Dowel pin

8. Oil seal

9. Pump housing

4-216