TM 5-3805-262-34

4-4. FRONT AND REAR AXLES DIFFERENTIAL ASSEMBLY MAINTENANCE

a. Differential Carrier.

This task covers disassembly, cleaning, inspection, re-

assembly, and adjustment of differential carrier.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Fixed open end wrench set

Screwdriver

Hand hammer, 16 ounces

Slip joint pliers

Mechanical puller kit

Safety glasses

Indicating dial scale, zero to 50 pounds

Torque wrench, 3/4 inch drive

Vise

Socket wrench

Socket wrench

Cold chisel, 3/4

Dial indicator

Hydraulic press

Sleeves

set, 3/4 inch drive

set, 3/8 inch drive

inch cut

Bearing collar remover

Flange holding tool

Torque wrench multiplier, 2000 lb-ft capacity

Chain hoist

Grinder

Micrometer, zero to 5 inches

Steel bar

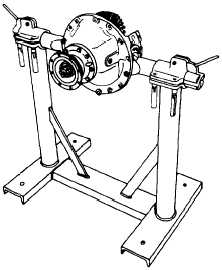

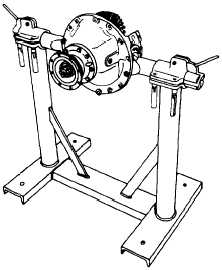

Repair stand

Wood block

Scrap wire

Cord or string

Capscrews, two, 7/16-20NF by one inch long

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Abrasive cloth, medium grit (Appendix C, item 8)

Hypoid gear oil (Appendix C, item 13)

Linseed oil (Appendix C, item 16)

Red lead (Appendix C, item 17)

Retaining compound (Appendix C, item 31)

Air drying adhesive (Appendix C, item 34)

NOTE

PRELIMINARY PROCEDURE: Differential as-

sembly removed (page 3-362 or 3-390) and

mounted in repair stand as shown.

4-218