TM 5-3805-262-34

2-13. STEERING SYSTEM TROUBLESHOOTING (CONT)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

3. SLOW OR HARD STEERING (Cont).

Step 3. (Cont).

c. If efficiency determined in above test is below 75 percent, re-

move and replace hydraulic pump (page 3-612). If efficiency is

above 75 percent, go to step 4 below.

Step 4.

Perform steering circuit and

a. If pressure readings are

flow control valve (page

b. If pressure readings are

cified in above test, go

relief valve test no. 2 (page 3-505).

not as specified in test no. 2, replace

3-566).

okay, and flow readings are not as spe-

to step 5 below.

Step 5.

perform steering cylinder tests (page 3-560).

a. If steering cylinders check okay, replace steering gear (page

3-510). Go to step 6 below.

b. If steering cylinders don’t check okay, replace defective steer-

ing cylinder (page 3-562).

Step 6.

Disassemble steering gear

(page 3-512).

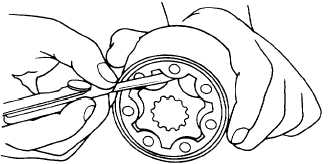

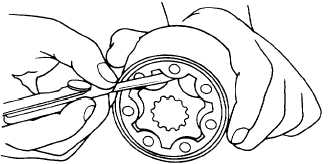

Inspect rotor and stator

for cracks, distortion, or

damage.

Put rotor in stator. Use

thickness gage to measure

clearance between rotor

and stator as shown.

Clearance must not exceed

0.005 inch.

a. If clearance between rotor and stator exceeds 0.005 inch, re-

place rotor and stator (page 3-518); replace rotor or stator if

cracked, distorted, or damaged (page 3-518).

b. If rotor and stator check okay, go to step 7 below.

Step 7.

Inspect drive shaft of steering gear for damaged gear teeth.

a. If gear teeth of drive shaft are damaged, replace drive shaft

(page 3-518).

b.

If gear teeth of drive shaft check okay, go to step 8 below.

2-116