TM 5-3805-262-34

INSTALLATION (SHEET 2 OF 2)

Position a piece of 0.003 inch shim stock between O-ring (7) and engine

block during installation to prevent “

after installation.

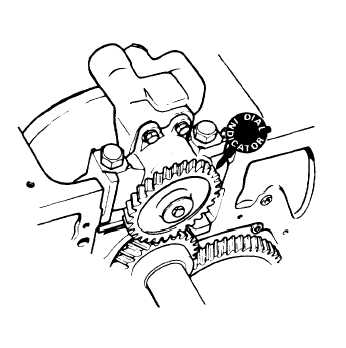

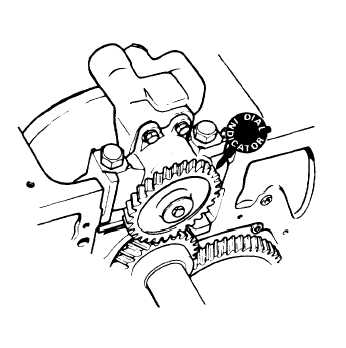

(e) Install oil pump (5)

with shims (6), cap-

screws (3), and new

washers (4) on main

bearing cap.

(f) Tighten capscrews (3)

195 to 215 lb-ft.

(g) Using dial indicator,

to

measure

backlash between oil pump (5)

drive gear and crankshaft

gear. If backlash is not 0.006

to 0.011 inch, add or remove

shims (6) until correct back-

lash is obtained.

(h) Install connector (2) in oil

pump (5). Tighten connector

(2) to 105 to 115 lb-ft.

damage to O-ring. Remove shim stock

(i) Install oil suction tube (1) on connector (2), with screen positioned as

noted during removal. Tighten oil suction tube (1) nut to 90 to 100 lb-

ft.

(j) Install oil pan (page 3-90).

(k) Install engine in loader (page 3-30).

3-95