TM 5-3805-262-34

DISASSEMBLY (SHEET

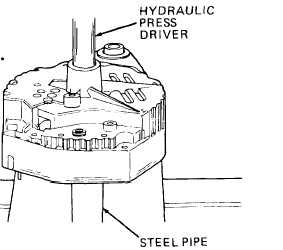

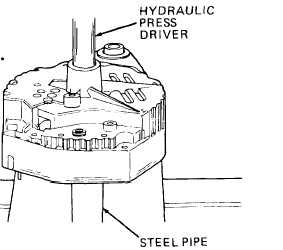

ac. Remove ball

(1) Cut a 3

4 OF 4)

bearing (49):

inch length of steel

pipe suitable for removal of

ball bearing. Inside diameter

of pipe must be larger than

ball bearing (49); outside

diameter of pipe must be small

enough to support center sec-

tion of drive end frame (52).

(2)

Support center section of

drive end frame (52) on

steel pipe.

(3) Press ball bearing (49)

ad.

ae.

af.

from drive end frame (52)

using appropriate driver

and hydraulic press.

Remove bearing plate (50) and gasket (51). Discard gasket (51).

At slip ring end frame (58), remove roll pin (53) and bushing (54).

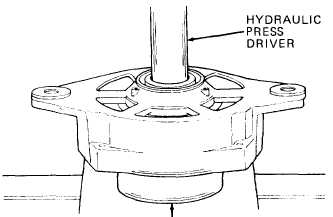

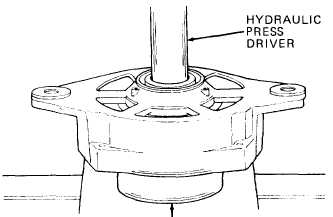

Remove needle bearing (56):

(1)

(2)

(3)

(4)

(5)

Cut a 4 inch length of steel pipe suitable

for removal of needle bearing. Inside di-

ameter of pipe must be larger than needle

bearing, seal, and plug; outside diameter

of pipe must be small enough to support

center section of slip ring end frame (58)

Support center section of slip

ring end frame (58) on steel

pipe.

Position appropriate driver on

plug (57).

Press seal (55), needle

bearing (56), and plug (57)

from slip ring end frame (58)

using hydraulic press.

Discard seal (55) and plug (57).

3-209