TM 5-3805-262-34

3-4. ALTERNATOR REPAIR (CONT)

INSPECTION/REPAIR (SHEET 5 OF 5)

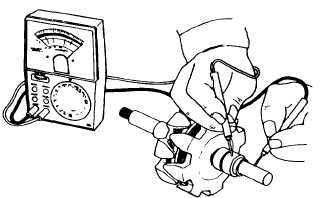

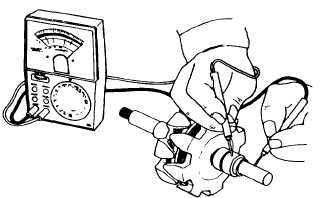

(3) Hold either multimeter lead on

one rotor slip ring, other mul-

timeter lead on rotor shaft.

Multimeter should indicate open

circuit (multimeter pointer

should not move).

1.

Inspect all other parts for distort

REASSEMBLY (SHEET 1 OF 5)

ion, damage, or cracks.

NOTE

Perform steps a through j below only if

end frame parts were removed; otherwise

go to step k below.

a.

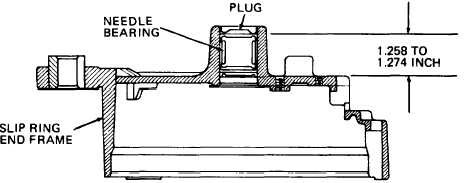

Install needle bearing (56):

(1)

(2)

(3)

(4)

(5)

(6)

3-214

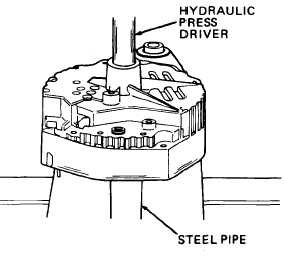

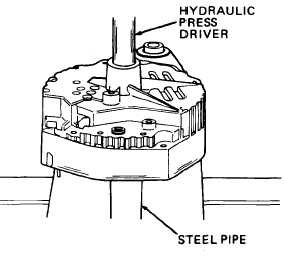

Support center section of slip

ring end frame (58) on steel

pipe.

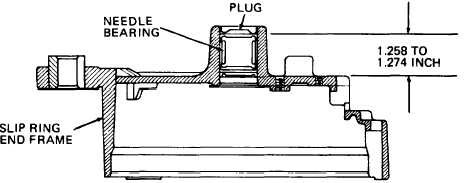

Apply clean engine oil to circum-

ference of needle bearing (56).

Position needle bearing (56) in slip ring end frame (58) bore.

Using hydraulic press and appropriate driver, press needle bearing (56)

to depth shown.

Fill plug (57) recess with clean lubricating grease and position over

needle bearing (56).

Press plug (57) into slip ring end frame (58) bore until flush with end

frame.