TM 5-3805-262-34

3-4. ALTERNATOR REPAIR (CONT)

REASSEMBLY (SHEET 2 OF 5)

b.

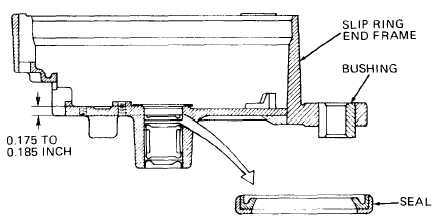

Install seal (55):

(1)

Invert slip ring end frame

and support center section

steel pipe.

(2)

Apply clean engine oil to

circumference of new seal

(55).

(3)

Position seal (55) in slip

frame (58) bore with seal l

(58)

on

ring end

ip down.

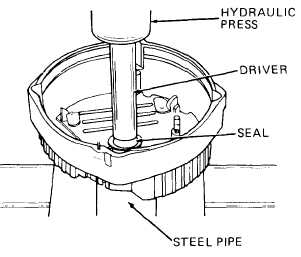

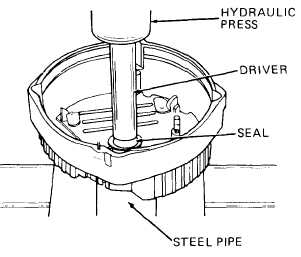

(4) Press seal (55) to depth shown using hydraulic press and appropriate

driver.

(5) Apply clean lubricating grease to seal (55) lip.

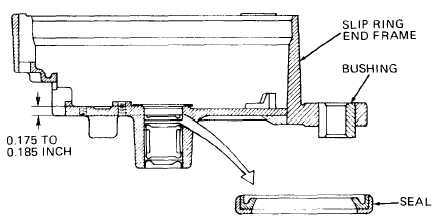

c.

Press bushing (54) flush with slip ring end frame (58) face as shown.

d.

Install roll pin (53) in slip ring end frame (58).

e.

Install ball bearing (49):

(1)

Position drive end frame (52) on hydraulic press table, open end up.

(2)

Install gasket (51) and bearing plate (50) in drive end frame (52).

(3) Apply clean engine oil to circumference of ball bearing (49).

(4)

Position ball bearing (49) in drive end frame (52) bore, closed side

down. If both sides of ball bearing are open, position ball bearing with

stamped number side up.

3-216