TM 5-3805-262-34

INSTALLATION

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

Wear protective goggles and gloves and use only in a well ventilated

area. Avoid contact with skin, eyes and clothes and don-t breathe

vapors. Do not use near open flame or excessive heat and don't smoke

when using it. Failure to do so could cause serious injury. If you be-

come dizzy while using cleaning solvent, get fresh air and medical

attention immediately. If contact with skin or clothes is made, flush

with large amounts of water.

If contact with eyes is made, wash eyes

with

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

water and get medical aid immediately.

Using clean cloth moistened with cleaning solvent P-D-680, clean charging

pump (4) mounting surface and machined surface on transmission. If neces-

sary, use putty knife to remove all gasket (5) residue.

Position new gasket (5) on charging pump (4) body. Put two lock washers

(2) and capscrews (3) through top of charging pump. These will be used as

guides to aline gasket with charging pump.

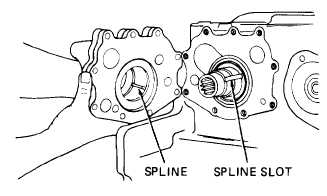

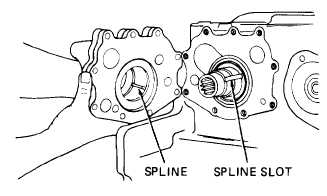

Position new gasket (5) and

charging pump (4) on transmis-

sion. Aline splines on charging

pump drive gear with spline

slots in transmission member.

Hand tighten two capscrews (3).

Install five lock washers (2)

and capscrews (3). Tighten five

capscrews (3) to 26 to 32 lb-ft;

don’t tighten two capscrews used

to secure rear wiring harness

mounting bracket to charging

pump (4).

Install two lock washers (2) and capscrews (1). Tighten capscrews to 26

to 32 lb-ft.

Install rear wiring harness mounting bracket on charging pump (page

3-275) and tighten two capscrews (3) to 26 to 32 lb-ft.

Install hydraulic pump on charging pump (page 3-613).

Fill transmission with lubricating oil (refer to TM 5-3805-262-20).

Install engine front side panels (refer to TM 5-3805-262-10).

3-345