TM 5-3805-262-34

3-11. SERVICE BRAKE SYSTEM MAINTENANCE (CONT)

b. Calipers.

This task covers disassembly, cleaning, inspection, and reassembly

of brake calipers.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Safety glasses

Key set, socket head screw

Fixed open end wrench set

Hand hammer, 16 ounces

Shop compressed air system

Wood block, 1 by 4 by 12 inches

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Abrasive cloth (Appendix C, item 8)

Brake fluid (Appendix C, item 19)

O-rings (FSCM 10988 PN 218-5004)

Brake seal kit (FSCM 52256 PN 9680382)

REFERENCE: TM 5-3805-262-20

NOTE

PRELIMINARY PROCEDURE: Brake calipers removed from loader (refer to TM

5-3805-262-20.

DISASSEMBLY (SHEET 1 OF 2)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Remove two piston plugs (1) and O-rings (2). Discard O-rings.

Using open end wrench, loosen and remove two piston caps (3) and O-rings

(4). Discard O-rings.

Push two pistons (7) from body (11) bores.

Remove and discard two O-rings (5), piston rings (6), and wipers (8).

Try to pull the other two pis-

tons (7) from body (11) bores

by hand. If successful go to

step (9) below. If not, go to

step (6) below.

Remove one bleeder valve (9).

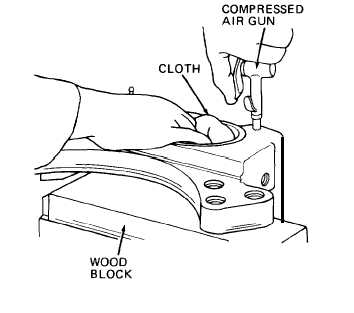

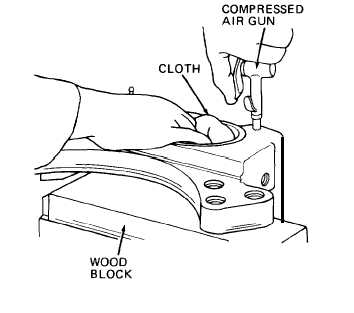

Place wood block on pistons (7)

as shown.

Using clean cloths, close off

air passages in body (11) and

apply compressed air to bleeder

valve (9) port to force pistons

(7) from body.

3-426