TM 5-3805-262-34

TEST NO. 2 - STEERING CIRCUIT AND RELIEF VALVE (SHEET 3 OF 5)

g.

Connect flowmeter (12) hoses (10 and 11) and adapters and assemble adapters

and nine inch return pipe (13) (p/o flowmeter fitting kit) as shown. Install

assembled parts (13) in fill cap opening of hydraulic reservoir.

h.

Install flowmeter in loader cab.

i.

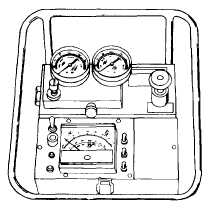

Set flowmeter controls as follows;

RANGE switch in HI position

ON/OFF switch in ON position

PRESSURE VALVE control completely open

FLOW switch in FLOW position

j.

Start and operate engine at idle speed.

k.

Press and hold flowmeter TEMPERATURE switch

and watch flowmeter TEMPERATURE gage. Gage

should indicate 130 degrees. If indication is

not correct go to step 1 below; if gage

indicates 130 degrees go to step m below.

Before performing following steps, warn personnel to stay away from

sides of loader between front and rear chassis. Failure to do so will

cause death or serious injury to those personnel due to chassis pivoting

and crushing them. If personnel are injured, obtain medical assistance

immediately.

l.

Depress accelerator pedal and increase engine speed to 1500 rpm. Turn

steering wheel completely to right until it cannot be turned anymore.

Continue to hold steering wheel for a full right turn. Close flowmeter

PRESSURE VALVE control until flowmeter PRESSURE gage indicates 1000 psi.

Watch flowmeter TEMPERATURE gage while depressing flowmeter TEMPERATURE

switch. Continue to operate engine at 1500 rpm until flowmeter gage indi-

cates 130 degrees then release accelerator pedal.

m.

Increase engine speed to full throttle.

n.

Turn steering wheel to right and slowly close flowmeter PRESSURE VALVE

control. As PRESSURE VALVE control is closed, flowmeter FLOW gage indication

will slowly decrease. When loader relief valve begins to open, flowmeter

FLOW gage reading will decrease rapidly. Stop closing flowmeter PRESSURE

VALVE control and record flowmeter PRESSURE gage reading. This reading is

the pressure at which relief valve begins to open.

3-507