TM 5-3805-262-34

3-21. CHECKS AND ADJUSTMENTS AND FLOWMETER TESTS (CONT)

e. Flowmeter Tests.

The following test will measure volume, pressure, and tem-

perature of hydraulic oil as it flows through the flowmeter. Test number 1 deter-

mines if there are any problems between the hydraulic reservoir and the loader sec-

tion of hydraulic pump and efficiency of hydraulic pump loader section. Test number

2 indicates if there are any problems in the loader circuits.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Fixed open end wrench set

Socket wrench set, 3/8 inch drive

Flowmeter (FSCM 45225 PN CAS-10280)

Fitting kit (FSCM 45225 PN CAS-10111)

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

NOTE

PRELIMINARY PROCEDURE: Control levers operated several times in both

directions to relieve hydraulic pressure, front access door unlocked and

open, and hydraulic reservoir fill cap loosened.

TEST NO. 1 - HYDRAULIC PUMP LOADER SECTION (SHEET 1 OF 4)

Dry cleaning solvent P-D-680 used to clean parts is toxic and flammable.

Wear protective goggles and gloves and use only in a well ventilated

area. Avoid contact with skin,

eyes and clothes and don’t breathe

vapors. Do not use near open flame or excessive heat and don’t smoke

when using it. Failure to do so could cause serious injury. If you

become dizzy while using cleaning solvent,

get fresh air and medical

attention immediately. If contact with skin or clothes is made, flush

with large amounts of water.

If contact with eyes is made, wash eyes

with water and get medical aid immediately.

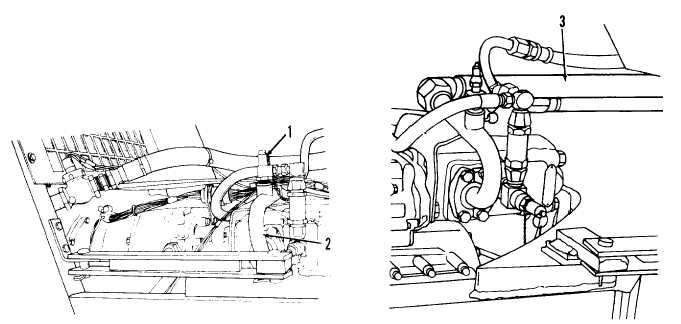

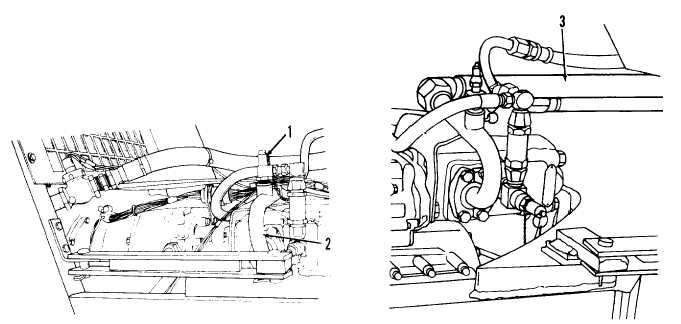

(1)

Using clean cloth moistened with

cleaning solvent clean all dirt

and grease from quick disconnect

coupling (1), tube (2), and inlet

hose (3) connection to tube (2).

3-627