TM 5-3805-262-34

SHEET 3 OF 3

(5)

(a)

(b)

(6)

(7)

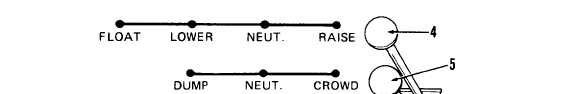

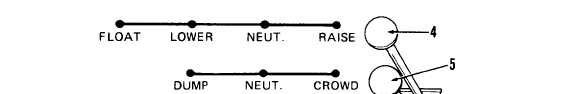

With engine operating at full throttle, ensure that LIFT ARM and BUCKET

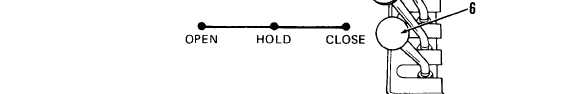

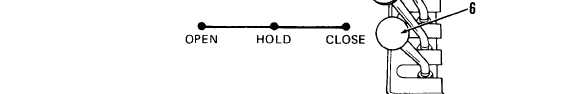

control levers (4 and 5) are in NEUT. position. Ensure that CLAM control

lever (6) is in HOLD position. Read pressure gage indication. Pressure

gage shall indicate less than 500 psi. If pressure gage indication is

less than 500 psi, go to step (6) below. If pressure gage indication is

more than 500 psi:

Move each control lever (4, 5, and 6) a small distance in both direc-

tions while watching pressure gage. If pressure gage reading does not

decrease, go to step (b) below. If pressure gage reading decreases, con-

trol levers and linkages are not adjusted correctly or the spool center-

ing spring is damaged. Check control levers and linkages adjustment

(page 3-720). If adjustment is okay, replace control valve assembly

(page 3-647).

Replace hydraulic filter (refer to TM 5-3805-262-20) and recheck neutral

pressure. If pressure is still high , remove hydraulic return lines and

check for dirt or other restrictions.

Turn off engine and operate hydraulic control levers several times to re-

lieve hydraulic pressure.

Disconnect pressure gage from quick disconnect coupling (1) and reinstall

cap on quick disconnect coupling.

3-623