TM 5-3805-262-34

3-21. CHECKS AND ADJUSTMENTS AND FLOWMETER TESTS (CONT)

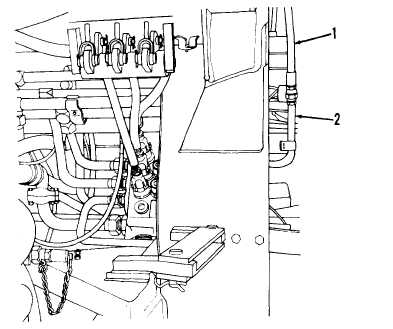

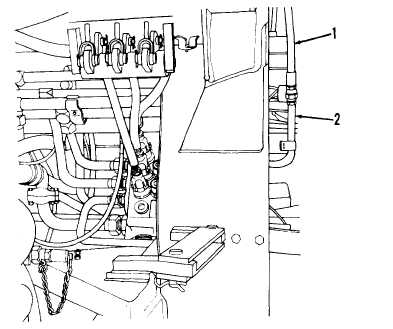

d. Circuit Relief Valves Pressure Setting Check and Adjustment (SHEET 1 OF 3).

This task covers checking and adjustment of control valve assembly circuit relief

valves pressure settings. There are four circuit relief valves used in the control

valve assembly. These are used to protect the clam and bucket circuits.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Fixed open end wrench set

Slip joint pliers

Drill, 1/2 inch capacity

Drill bit, 1/4 inch diameter

Drive pin punch, 1/8 inch point

Hand pump (FSCM 45225 PN CAS-10090)

Fitting kit (FSCM 45225 PN CAS-10111)

Adjusting tool (fabricate from 1/2 inch Allen wrench, 1-1/2 inches long

with a 3/8 inch diameter hole drilled completely through it)

Pipe plug

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Expansion plug (FSCM 10988 PN 41-14)

NOTE

PRELIMINARY PROCEDURE: Control levers operated several times in both di-

rections to relieve hydraulic pressure, front access door unlocked and

open, and hydraulic reservoir fill cap loosened.

Hydraulic system pressure is over

2000 psi and hydraulic reservoir

is pressurized with compressed

air.

Before loosening or

disconnecting any hydraulic

hoses, lines, or fittings,

operate all hydraulic control

levers to relieve hydraulic

system pressure. Failure to do so

could cause serious injury or

death. If you are injured obtain

medical assistance immediately.

NOTE

Ensure that hand pump is full of

hydraulic oil and that tempera-

ture of hand pump hydraulic oil

is between 70 to 80 degrees F.

(1) Disconnect line between cylinder and control valve assembly in the cir-

cuit in which the circuit relief valve is to be checked:

NOTE

Clean all dirt and grease from hose and tube fittings before discon-

necting them.

3-624