TM 5-3805-262-34

3-24. TILT CYLINDER ASSEMBLIES MAINTENANCE

This task covers disassembly, cleaning, inspection, repair, and reassembly of tilt

cylinder assemblies.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Safety glasses

Torque wrench, 3/4 inch drive

Hand hammer, 3 pounds

Torque wrench, 1/2 inch drive

Vise jaw caps

Vise

Automotive Mechanic-s Tool Kit

Socket wrench set, 1/2 inch drive

Rubber mallet

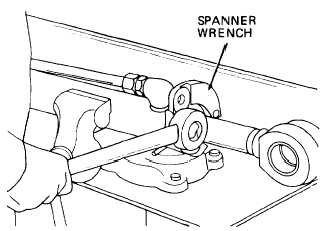

Spanner wrench (FSCM 10988 PN D4411O)

Rod, 2-3/8 inches diameter

Rod, 2-3/4 inches diameter

Torque wrench multiplier, 2000 lb-ft capacity

Chain

Support stand

Bore gage

Micrometer,

zero to 5 inches

MATERIALS/PARTS: Clean cloths (Appendix C, item 1)

Cleaning solvent P-D-680 (Appendix C, item 2)

Abrasive cloth, medium grit (Appendix C, item 8)

Lubricating oil (Appendix C, item 15)

Retaining compound (Appendix C, item 31)

Seal kit (FSCM 10988 PN G105513)

REFERENCE: TM 5-3805-262-20

PRELIMINARY PROCEDURE:

5-3805-262-20).

DISASSEMBLY (SHEET 1 OF 3)

a.

b.

NOTE

Tilt cylinder assemblies removed (refer to TM

Do not overtighten vise when

performing following step.

Overtightening will distort

cylinder tube (19).

Put tilt cylinder assembly in vise.

Using spanner wrench, unscrew gland

(14) from cylinder tube (19).

3-722