TM 5-3805-262-34

4-1. ENGINE MAINTENANCE (CONT)

b. Cylinder Sleeves. This task covers removal, cleaning, inspection, and instal-

lation of cylinder sleeves.

TOOLS: No. 1 Common Organizational Maintenance Tool Kit

Drill, 3/8 inch capacity

Torque wrench, 1/2 inch drive

Automotive Mechanic's Tool Kit

Socket wrench set, 1/2 inch drive

Ball (FSCM 10988 PN A28312)

Bore gage

Clamp bar (fabricate as shown)

Clamping disk (FSCM 45225 PN OTC970-14C)

Dial indicator

Micrometer, zero to 5 inches

Power brush deglazer (FSCM 10988 PN A42453)

Sleeve puller

Capscrews, three, 5/8-11 by 3/4 inch (FSCM 10988 PN 13-1012)

Washers, flat, three, 1-3/4 inches OD, 11/16 inch ID, 9/64 inch

thick (FSCM 10988 PN 95-10)

MATERIALS/PARTS : Clean cloths (Appendix C, item 1)

Detergent (Appendix C, item 4)

Engine lubricating oil, OE/HDO 40 (Appendix C, item 9)

Lubricating oil, OE/HDO 10 (Appendix C, item 15)

Paint (Appendix C, item 22)

Oil-soluble grease (Appendix C, item 26)

Piston-sleeve kit (FSCM 10988 PN A166122)

NOTE

PRELIMINARY PROCEDURE: Oil pump removed (page 3-91), crankshaft and main

bearings removed (page 4-16), and camshaft and bearings removed (page

4-54) .

REMOVAL

NOTE

Perform steps (1) and (2) below for each

cylinder sleeve to be replaced. Do not

remove cylinder sleeve unless inspection

indicates need for replacement; cylinder

sleeves may be cleaned and inspected

without being removed from cylinder block.

(1) Mark cylinder sleeves (1) in

relation to their position in

cylinder block using paint if

sleeves are to be reinstalled.

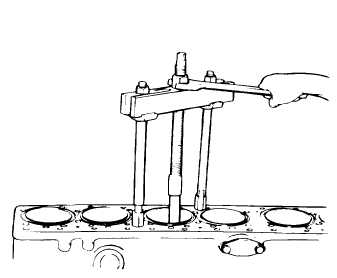

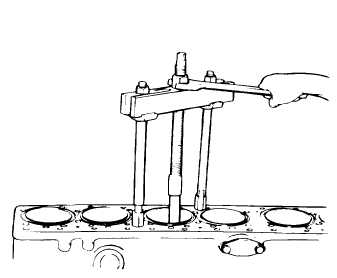

(2) Using sleeve puller, remove cylinder sleeve (1) from cylinder block.

(3) Remove and discard three O-rings (2).

4-6