CLEANING (SHEET 1 OF 2)

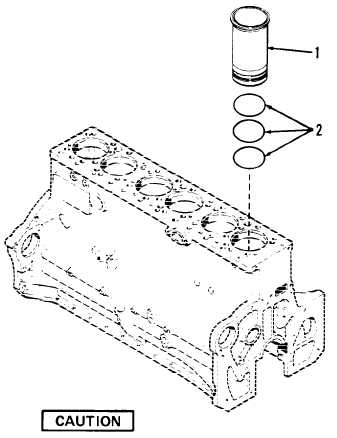

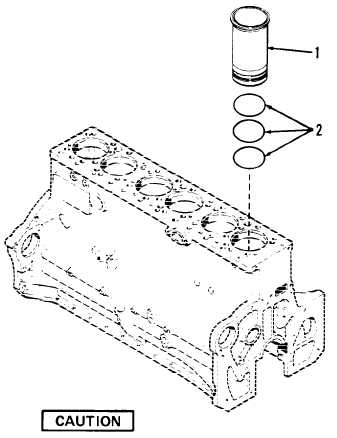

LEGEND

1. Cylinder sleeve

2. O-rings (3)

TM 5-3805-262-34

If crankshaft has not been removed,

cover crankshaft journals using

clean cloths before deglazing cylinder sleeves. Abrasives and dirt

resulting from deglazing operation can cause damage to crankshaft

journals.

NOTE

Glaze must be removed from cylinder sleeves so that piston rings can

properly seat themselves within a reasonable period of run-in time.

Excessive oil consumption results from glaze build-up by not allowing

piston rings to seat properly in cylinder sleeves.

(1) If necessary to remove glaze from cylinder

sleeve (1) walls:

(a) With cylinder sleeve (1) installed in

cylinder block, apply OE/HDO 40 oil

to cylinder sleeve walls.

(b) Use 3/8 to 1/2 inch drill at 350 to

500 rpm to power brush deglazer;

start brush rotation and lower

brush into cylinder sleeve.

(c) Brush up and down at a pace of

approximately 40 strokes per

minute for 20 to 30 seconds.

4-7