TM 5-3805-262-34

INSTALLATION (SHEET 2 OF 2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(lo)

(11)

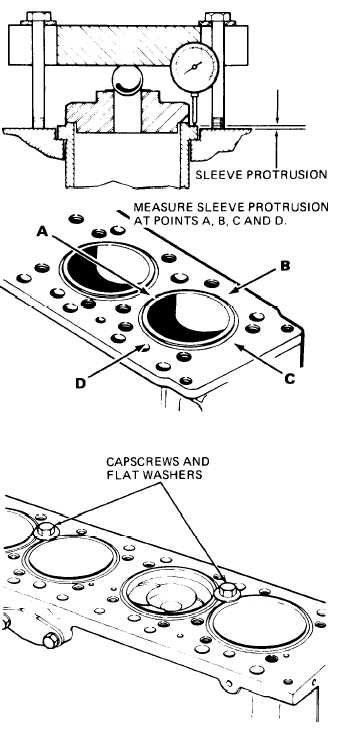

With clamping disk, ball, and

clamp bar positioned, measure

cylinder sleeve (1) protrusion

using dial indicator. Make four

measurements 90 degrees apart

as shown. Sleeve protrusion

must be 0.000 to 0.006 inch.

Replace cylinder sleeve (1) if

protrusion does not meet this

range.

Remove capscrews, clamp bar,

ball, clamping disk, and cylin-

der sleeve (1) from cylinder

block.

Install three new O-rings (2)

on cylinder sleeve (1) bottom

grooves.

Use oil-soluble grease and lu-

bricate three O-rings (2) and

cylinder block lower bore cham-

fer.

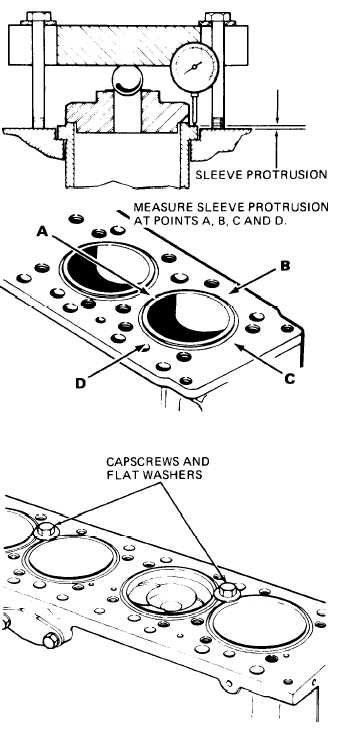

Using only the palms of your

hands, push cylinder sleeve (1)

into cylinder block. Install

flat washers and capscrews to

hold cylinder sleeves in

position.

Install camshaft and bearings

(page 4-63).

Install pistons and connecting

rods (page 4-50). Don’t forget

to remove capscrews and washers

holding cylinder sleeves in

position.

Install crankshaft and main

bearings (page 4-26).

Install oil pump (page 3-94).

4-11