TM 5-3805-290-10

OPERATION UNDER USUAL CONDITIONS - CONTINUED

0005 00

LOWERING LOADER ARM WITH ENGINE STOPPED - CONTINUED

2.

No Electrical Power/Accumulator Discharged.

a.

Park machine on level ground.

b.

Lower work tool to the ground.

c.

Engage parking brake.

d.

If there is no electrical power or accumulator is discharged, loader arm must be lowered manually.

e.

To lower loader arm manually, perform the following steps:

(1)

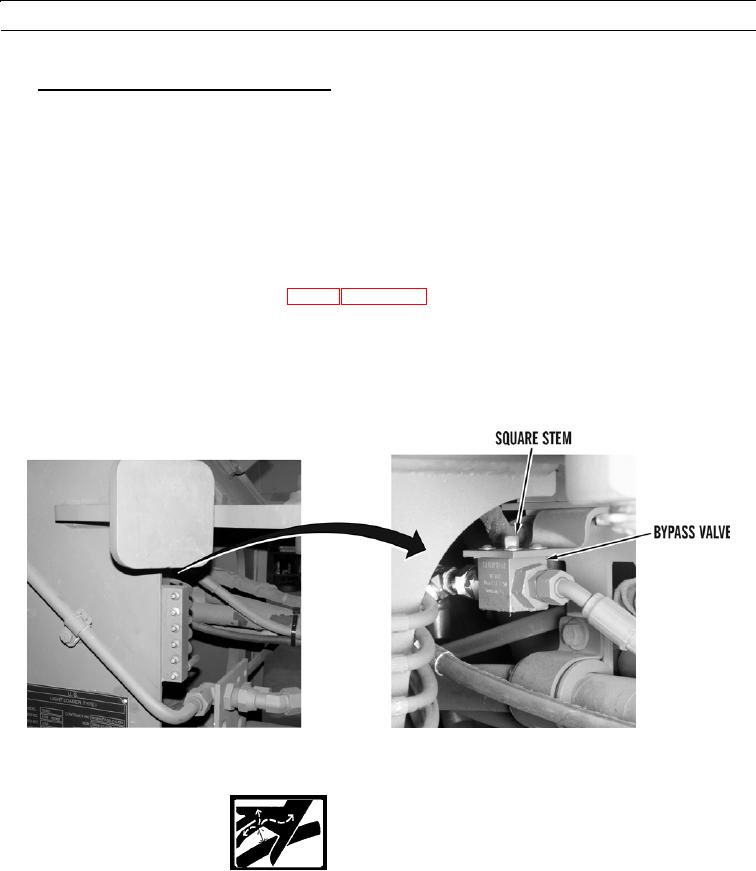

Locate bypass valve at center of machine, on front frame section just forward of articulation area on left

side.

(2)

Use adjustable wrench (Item 11, Table 2, WP 0030 00) to turn square stem on top of bypass valve clock-

wise (to the right) 90 degrees.

(3)

Loader arm will begin to lower when bypass valve is open.

(4)

After loader arm has lowered, turn square stem of bypass valve counterclockwise (to the left) 90 degrees to

close valve.

427-B0550

RELIEVING HYDRAULIC SYSTEM PRESSURE

0005 00

WARN I N G

DO NOT disconnect or remove any hydraulic system line or fitting unless engine is shut down and hydraulic

system pressure has been relieved. Tighten all connections before applying pressure. Escaping hydraulic fluid

under pressure can penetrate the skin, causing injury or death to personnel.

Never leave operator compartment without engaging parking brake. Failure to follow this warning may result

in injury or death to personnel.