TM 5-3805-290-10

OPERATION UNDER USUAL CONDITIONS - CONTINUED

0005 00

QUICK COUPLER OPERATION - CONTINUED

g.

Press bottom of quick coupler control switch, to engage (lock) quick coupler pins into retainer holes of work tool.

N OT E

While seated inside cab, operator can visually check that quick coupler pins are engaged into work tool.

h.

To check for correct engagement of quick coupler to work tool, perform the following steps:

(1)

Tilt work tool downward onto ground and apply slight downward pressure.

(2)

Slowly back up machine.

(3)

If there is movement between work tool and quick coupler pins, engagement is not complete. Disengage

and repeat procedure.

i.

Shut down engine.

j.

Engage parking brake.

WARN I N G

DO NOT disconnect or remove any hydraulic system line or fitting unless engine is shut down and hydrau-

lic system pressure has been relieved. Tighten all connections before applying pressure. Escaping hydraulic

fluid under pressure can penetrate the skin, causing injury or death to personnel.

k.

Relieve hydraulic system pressure. Refer to

Relieving Hydraulic System Pressure earlier in

this work package.

l.

Rotate coupling to align and disconnect quick

disconnects.

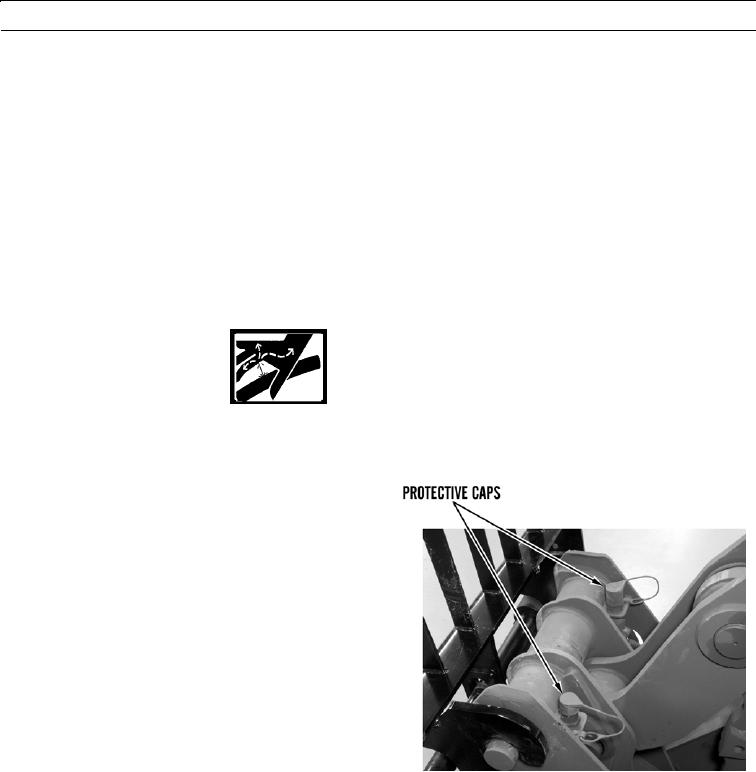

m.

If necessary, remove protective caps from quick

disconnect fittings on quick coupler and MP

bucket.

427-B0552

0005 00-13