TM 5-3805-290-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

ELECTRICAL POWER SUPPLY CIRCUIT TEST

0013 00

N OT E

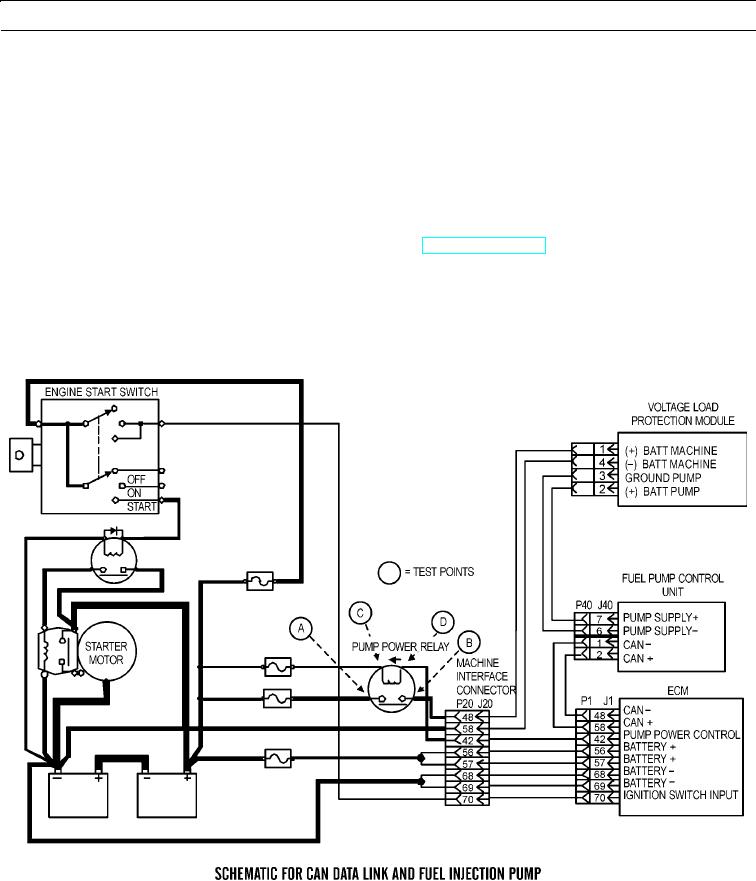

ECM receives electrical power (battery voltage) through wiring supplied by engine harness. ECM input at

connector P1:70 (engine start switch) receives battery voltage from engine start switch when engine start

switch is in ON position or START position. When ECM detects battery voltage at this input, ECM will power

up. When battery voltage is removed from this input, ECM will power down.

Cause of intermittent power supply to ECM can occur on either positive side (unswitched +battery) or nega-

tive side (-battery). Both sides are routed from ECM to battery. Three connections for unswitched +battery

should be routed through dedicated protection circuit.

Engine ECM requires engine start switch to be in ON position (TM 5-3805-290-10) to maintain communica-

tions.

For intermittent problems such as intermittent shutdowns that could be caused by engine wiring, temporarily

bypassing engine wiring may be effective means of determining cause. If symptoms disappear with bypass

wiring, engine wiring is cause of problem. Means of bypassing engine wiring is explained in this test proce-

dure.

427-B0676