TM 5-3805-290-23-1

ELECTRICAL SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0013 00

ELECTRIC STARTING SYSTEM TEST

0013 00

N OT E

All electrical starting systems have four elements: ignition switch, start relay, starting motor solenoid, and

starting motor.

Engine start switches have capacity of 5 to 20 amperes. Start relay coil draws approximately 1 ampere

between test points. Start reply switch contacts for starting motor are rated between 100 and 300 amperes.

Start relay can easily switch load of 5 to 50 amperes for starting motor solenoid.

Starting motor solenoid is switch with capacity of approximately 1,000 amperes. Starting motor solenoid sup-

plies power to starter drive. Starting motor solenoid also engages pinion to engine flywheel.

Starting motor solenoid has two coils. Pull-in coil draws approximately 40 amperes. Hold-in coil requires

approximately 5 amperes.

When magnetic force increases in both coils, pinion gear moves toward ring gear of flywheel. Then, solenoid

contacts close to provide power to starting motor. When solenoid contacts close, ground is temporarily

removed from pull-in coil. Battery voltage is supplied on both ends of pull-in coil while starting motor cranks.

During this period, pull-in coil is out of circuit.

Engine cranking continues until current to solenoid is stopped by releasing engine start switch.

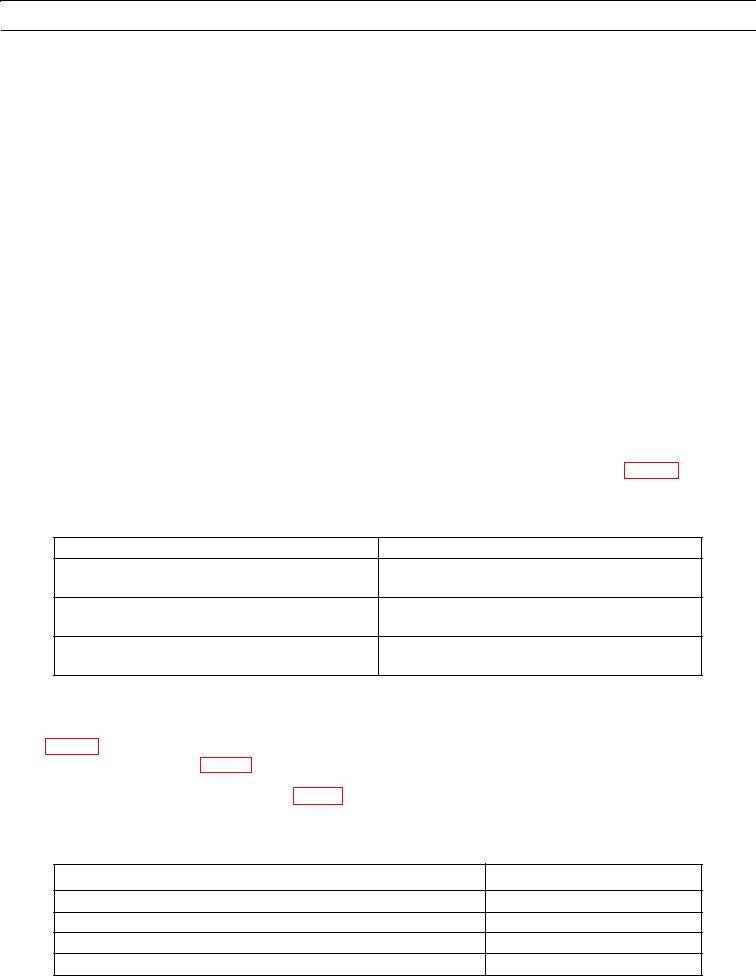

Power available during cranking varies according to temperature and condition of batteries. Table 2 shows

voltages expected from battery at various temperature ranges.

Table 2. Typical Electrical System Voltage During Cranking at Various Ambient Temperatures.

TEMPERATURE

VOLTAGE

-10 to 20F

12 to 16V

(-23 to -7C)

20 to 50F

14 to 18V

(-7 to 10C)

50 to 80F

16 to 24V

(10 to 27C)

N OT E

Table 3 shows maximum acceptable loss of voltage in battery circuit. Battery circuit supplies high current to

starting motor. Values in Table 3 are for engines which have service of 2,000 hours or more.

Voltage drops greater than the amounts in Table 3 are caused most often by loose connections, corroded con-

nections, and faulty switch contacts.

Table 3. Maximum Acceptable Voltage Drop in Starting Motor Circuit During Cranking.

Circuit

24V System

Battery post "-" to starting motor terminal "-"

1.4V

Drop across disconnect switch

1.0V

Battery post "+" to terminal of starting motor solenoid "+"

1.0V

Solenoid terminal "Bat" to solenoid terminal "Mtr"

0.8V