TM 5-3805-290-23-1

HYDRAULIC SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0017 00

GENERAL - CONTINUED

5.

Stop engine and engage parking brake (TM 5-3805-290-10).

6.

Turn engine start switch to ON position without starting engine. Move control levers through full range of travel (TM 5-

3805-290-10). Repeat movement of levers several times to discharge accumulator for pilot system. This will relieve any

pressure that may be present in work tool hydraulic system.

PISTON PUMP PRESSURE TEST AND ADJUSTMENT

0017 00

1.

Purging Process for Implement System.

a.

Connect steering frame lock (TM 5-3805-290-10).

b.

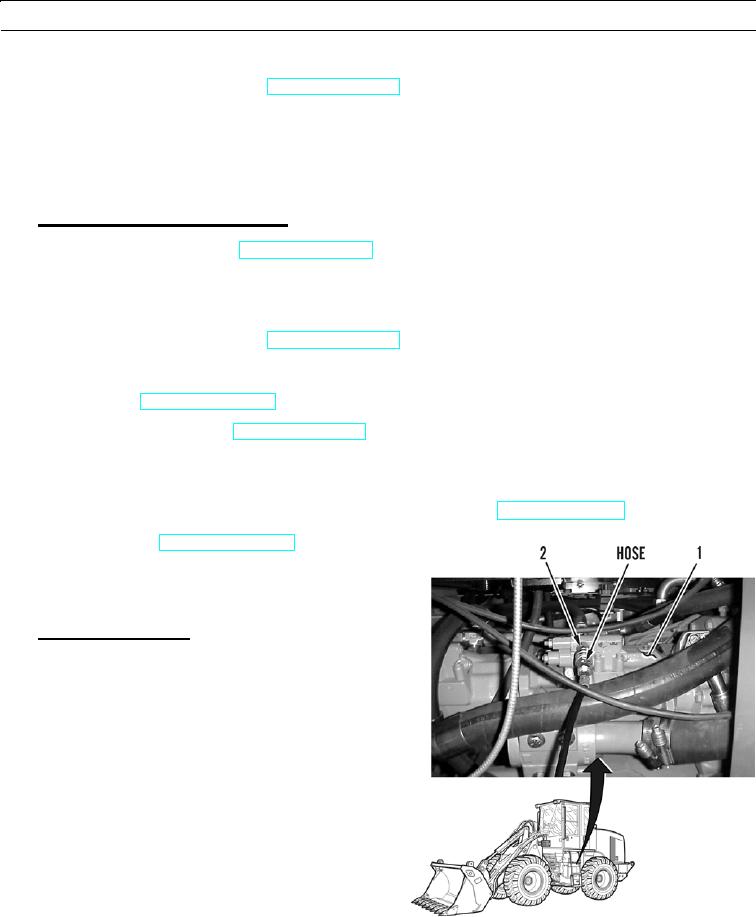

Remove left chassis covers (WP 0107 00) for access to piston pump (1).

c.

Connect end of hose to test port (2) for piston pump (1) signal pressure.

d.

Remove cap from hydraulic tank (TM 5-3805-290-10).

e.

Place other end of hose assembly into hydraulic tank.

f.

Start engine (TM 5-3805-290-10).

g.

Raise work tool off ground (TM 5-3805-290-10).

h.

Move work tool to RACK BACK position. Hold work tool in RACK BACK position for 30 seconds (TM 5-3805-

290-10).

i.

Tilt work tool forward until level to ground. Lower lift arms to ground (TM 5-3805-290-10).

j.

Shut off engine (TM 5-3805-290-10).

k.

Remove hose assembly from tank and pump.

l.

Install cap on hydraulic tank (TM 5-3805-290-

10).

2.

Signal Limiter Pressure.

a.

Connect pressure gage to hose.

b.

Connect other end of hose assembly to test port

(2) for piston pump (1) signal pressure.

427-B0958

c.

Adjust pump cutoff pressure to 4,350 psi (30,000 kPa). Refer to step 3.