TM 5-3805-290-23-1

HYDRAULIC SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0017 00

PISTON PUMP PRESSURE TEST AND ADJUSTMENT - CONTINUED

d.

Start engine (TM 5-3805-290-10).

e.

Raise lift arms and move work tool fully to TILT BACK position (TM 5-3805-290-10). Hold work tool against

stops.

f.

Observe signal oil pressure on pressure gage. Pressure should be 3,450 50 psi (23,750 350 kPa).

(1)

If signal oil pressure is correct, tilt work

tool forward until level to ground. Lower

lift arms to ground. Stop engine (TM 5-

3805-290-10). Remove test equipment.

(2)

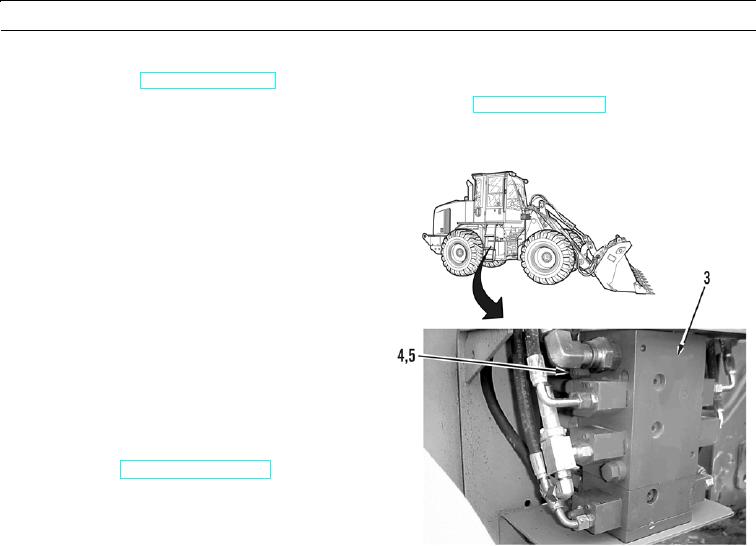

If pressure is not correct, adjust signal

limiter valve (3). Pressure should be

3,450 50 psi (23,750 350 kPa).

Loosen locknut (4). Rotate adjusting

screw (5) clockwise to increase pressure.

Rotate adjusting screw counterclockwise

to decrease pressure. Tighten locknut.

Repeat procedure until pressure is within

tolerances.

(3)

When signal oil pressure is correct, tilt

work tool forward until level to ground.

Lower lift arms to ground. Stop engine

Remove

test

equipment.

427-B0955

0017 00-4