TM 5-3805-290-23-1

HYDRAULIC SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0017 00

PISTON PUMP PRESSURE TEST AND ADJUSTMENT - CONTINUED

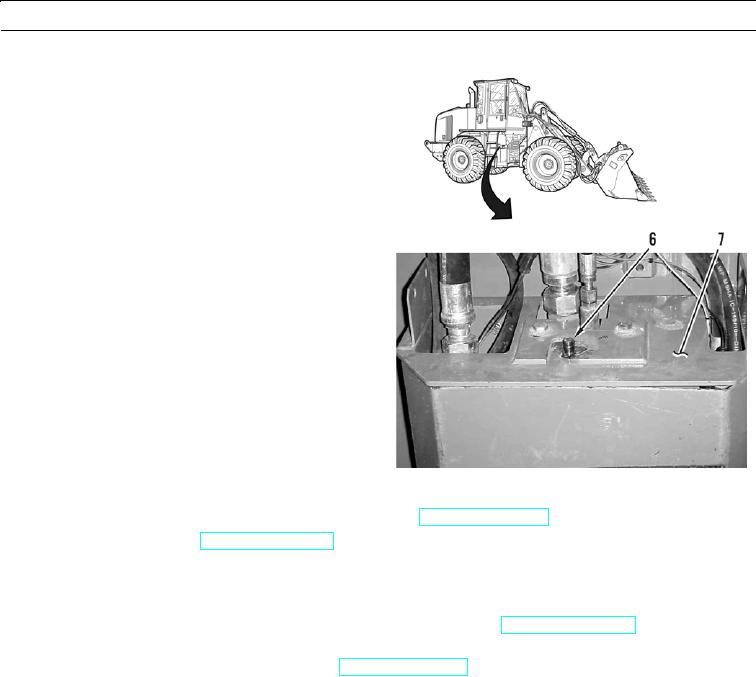

c.

Connect another hose to pressure tap (6) for

pump output located on top of bank valve (7).

Connect pressure gage to other end of hose

assembly.

427-B0956

d.

Run engine until normal operating temperature is reached (TM 5-3805-290-10).

e.

Raise lift arms slowly (TM 5-3805-290-10).

f.

Maximum signal oil pressure should be 3,450 50 psi (23,750 350 kPa). Maximum pump output pressure

should be 3,750 50 psi (25,850 350 kPa). Difference between two gages is margin pressure. Margin pressure

should be 290 15 psi (2,000 103 kPa).

g.

If margin pressure is correct, lower lift arms to ground. Stop engine (TM 5-3805-290-10). Remove diagnostic

equipment.

h.

If margin pressure is not correct, stop engine (TM 5-3805-290-10). Proceed to step 6.

0017 00-7