TM 5-3805-290-23-2

PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)

INCLUDING LUBRICATION INSTRUCTIONS - CONTINUED

0020 00

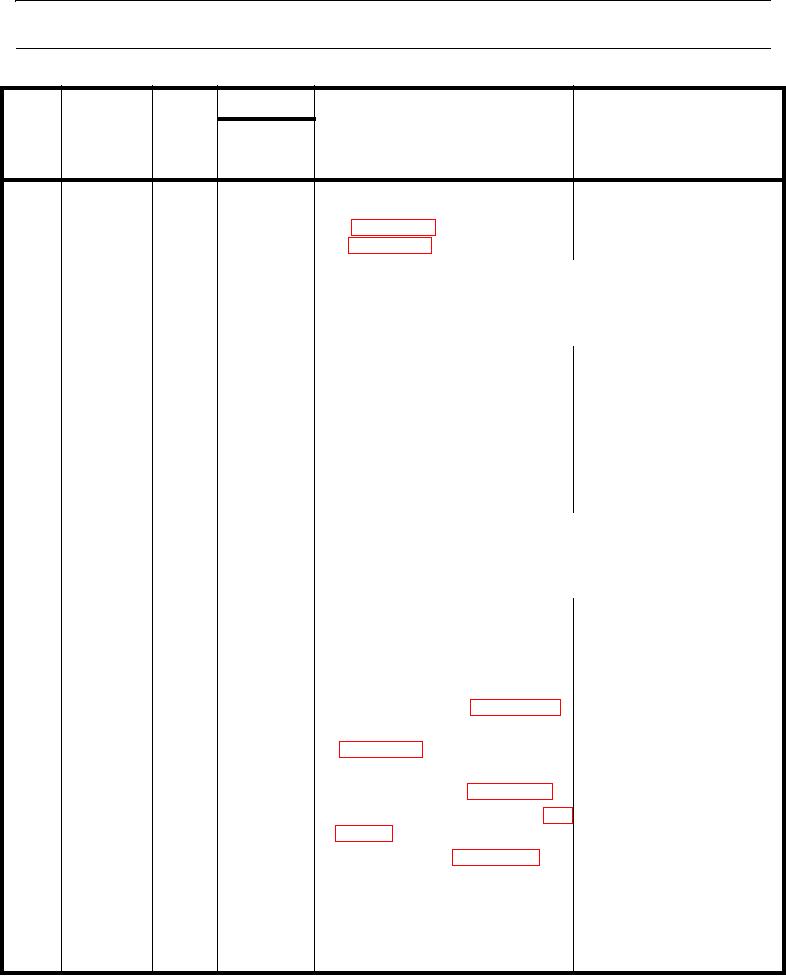

Table 1. Unit Preventive Maintenance Checks and Services (PMCS) for the 924G Wheel Loader - Continued.

LOCATION

ITEM TO

CHECK/

ITEM

MAN-

NOT FULLY MISSION

SERVICE

NO.

INTERVAL HOURS

PROCEDURE

CAPABLE IF:

Engine Valve Notify Direct Support Maintenance to

8

1,000 Hours

check intake/exhaust valve lash adjust-

or

Lash

ment (WP 0155 00) and inspect crankcase

Semiannual

vent (WP 0024 00).

CAU T I ON

9

1,000 Hours

Rollover Pro-

or

tective Struc-

Do not straighten ROPS. Do not repair ROPS by welding reinforce-

Semiannual

ture (ROPS)

ment plates to ROPS. Any repair to ROPS will not return ROPS to

its original condition. A damaged ROPS must be replaced.

a. Inspect ROPS for cracks, breaks, or

bends.

b. Replace ROPS if cracks, breaks, or ROPS has cracks, breaks, or

bends are evident (TM 5-3805-290- bends.

10).

c. At four corners inside cab, inspect Bolts missing, loose, or damaged.

ROPS for missing, loose, or damaged

mounting bolts (TM 5-3805-290-10).

CAU T I ON

ROPS mounting bolt threads should be coated with oil before

installing bolts. Failure to apply antiseize to bolt threads can result

in improper bolt torque.

d. Replace any damaged or missing bolts

with original equipment parts ONLY.

Tighten bolts to 340 lb-ft (461 Nm).

Once you have tightened all bolts,

tighten bolts again to correct torque.

Transmission a. Drain transmission oil (WP 0083 00).

10

1,000 Hours

1.0

or

Hour

b. Replace transmission oil filter element

Semiannual

c. Remove, clean, and reinstall transmis-

sion magnetic screen (WP 0084 00).

d. Replace transmission breather (WP

e. Refill transmission (WP 0083 00).

0020 00-5