TM 5-3805-290-23-2

ROCKER ARMS AND PUSH RODS MAINTENANCE - CONTINUED

0156 00

INSTALLATION - CONTINUED

N OT E

Ensure that pushrods are installed in original location and seated in valve lifters correctly.

2.

Lubricate new oil seal (4) with clean engine oil and install in oil supply hole in cylinder head (5).

3.

Position rocker shaft assembly (3) on cylinder head (5). Make sure that connection for oil supply is installed correctly

into oil seal.

CAU T I ON

Ensure that adjustment screws are properly seated in ends of pushrods.

It may be necessary to loosen adjustment screws on each rocker arm. This will help prevent a bent valve

or pushrod during installation of rocker shaft.

4.

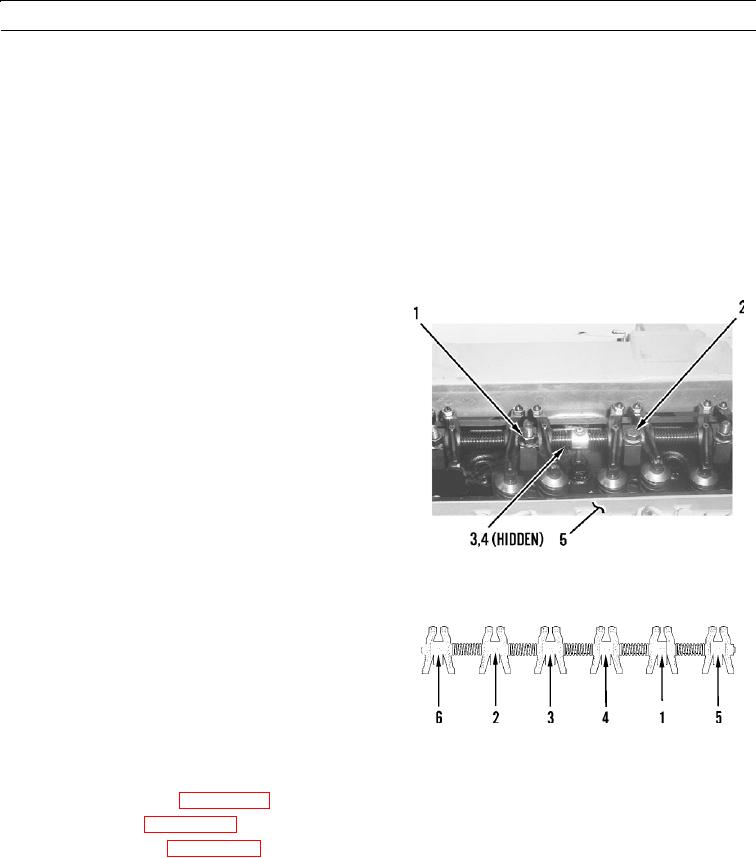

Lubricate five nuts (1) and bolt (2) with clean engine

oil.

5.

Install five nuts (1) and bolt (2).

427-B0513

6.

Tighten five nuts and bolt according to sequence in

illustration. Tighten five nuts and bolt on aluminum

bracket to 30 lb-ft (40 Nm). Tighten five nuts and bolt

on cast iron or steel bracket to 55 lb-ft (75 Nm).

427-B1305

7.

Adjust intake valve lash (WP 0155 00).

8.

Install valve cover (WP 0024 00).

9.

Check engine oil level (WP 0025 00).

10.

Run engine until normal operating temperature is reached (TM 5-3805-290-10).

11.

Shut down engine (TM 5-3805-290-10).

12.

Check for leaks.

END OF WORK PACKAGE

0156 00-5/(0156 00-6 Blank)