TM 5-3805-291-23-1

BRAKE SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0015 00

BRAKE SYSTEM AIR PURGE - CONTINUED

427-C2042

OPERATIONAL CHECKS (BRAKING AND HYDRAULIC FAN SYSTEM)

0015 00

N OT E

When diagnosing problem in braking and hydraulic fan system, visual inspection of system is first step.

Before any tests are performed, visually inspect entire brake and hydraulic fan systems for oil leaks and

damaged parts.

1.

Check oil level in sight gage (TM 5-3805-291-10).

2.

Look for air in oil of hydraulic tank immediately after engine is stopped. Use clear container to obtain sample of oil.

Look for air bubbles in oil.

3.

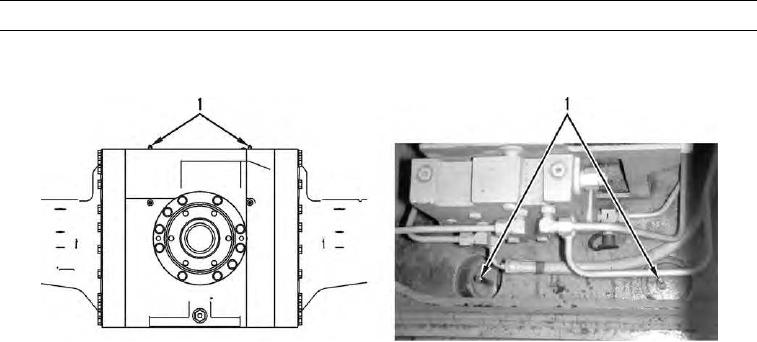

Check all oil lines and connections for damage and leaks.

4.

Inspect braking and hydraulic fan pump (WP 0215 00) for damage and inspect hydraulic fan motor (WP 0192 00) for

damage.

5.

Start engine and raise work tool (TM 5-3805-291-10).

6.

Ensure fan is operating.

7.

Disengage parking brake and activate service brakes while machine is moving in both directions. Listen for any unusual

noises. Ensure brakes stop machine within acceptable distance.

8.

Lower work tool and stop engine (TM 5-3805-291-10).