TM 5-3805-291-23-1

BRAKE SYSTEM TESTS, INSPECTIONS, AND ADJUSTMENTS - CONTINUED

0015 00

BRAKE CONTROL MANIFOLD TEST

0015 00

WARN I N G

Escaping fluid under pressure, even a pinhole sizeleak, can penetrate body tissue, causing serious

injury and possible death. If fluid is injected into your skin, it must be treated immediately by a

doctor familiar with this type of injury.

Always use a board or cardbo rd when checking for a leak.

a

Injury or death can result if two p rsons are not used in this procedure.

e

C AU T I O N

Care must be taken to ensure that fluids arecontained during performance of inspection, mainte-

nance, testing, adjusting, and repair of product. Be prepared to collect fluid with suitable contain-

ers before opening any compartment or disassembling any component containing fluids.

Dispose of all fluids accordingto local regulations and mandates.

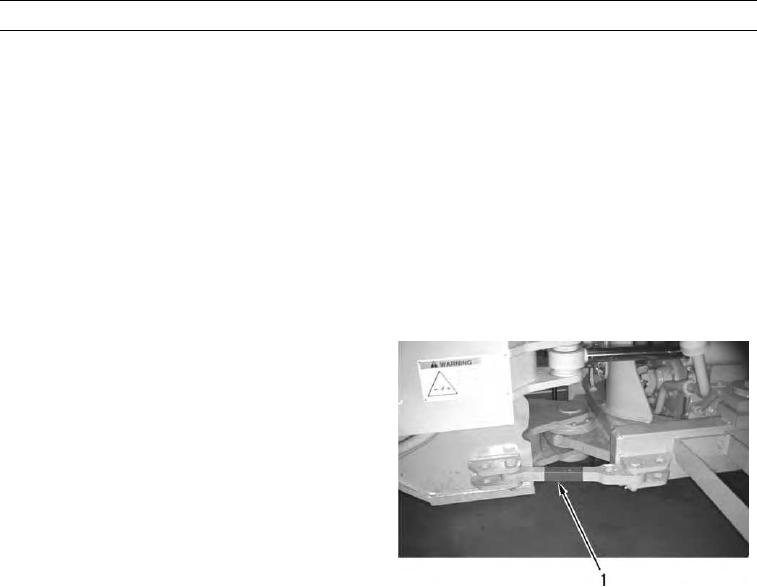

1.

Connect steering frame lock (1) (TM 5-3805-291-10).

2.

Depress brake pedal repeatedly in order to release all

oil pressure from brake circuit.

3.

Remove protective cap from test port (2) to test ser-

vice brake control manifold.

427-C0891

N OT E

Oil pressure must be 0 psi (0 kPa).

4.

Install 0 to 5,800 psi (0 to 40,000 kPa) pressure gage on test port (2).

5.

With assistance, start engine and immediately raise rpm to high idle (TM 5-3805-291-10).

N OT E

Correct service brake control manifoldcut-out pressure should be 2,200 50 psi (15,000 345

kPa).

Oil must increase to maximum. This is the cu-out pressure of the brake accumulator charging

t

valve.

6.

Record highest pressure. This is service brake control manifold cut-out pressure.

N OT E

Correct service brake control manifoldcut-in pressure should be 1,850 50 psi (12,800 345

kPa).

Pressure should drop consistently every time brake pedal is depressed.