TM 5-3805-291-23-1

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

ELECTRICAL CONNECTORS INSPECTION (ENGINE) - CONTINUED

2.

Check Wires for Damage to Insulation.

a.

Carefully inspect each wire for signs of abrasion, nicks, and cuts. Also, inspect wires for the following conditions:

(1)

Exposed insulation

(2)

Rubbing of wire against engine

(3)

Rubbing of wire against sharp point

b.

Check all wiring harness fasteners in order to verify harness is properly secured. Also check all fasteners in order

to verify harness is not compressed. Pull back harness sleeves in order to check for a flattened portion of wire. A

fastener that has been overtightened flattens harness. This damages wires that are inside harness.

c.

Expected Result. Wires are free of abrasion, nicks, and cuts and harness is properly clamped.

(1)

If the harness is OK, proceed to step 3.

(2)

If there is damage to harness, repair wires or replace wires, as required. Verify repair eliminates problem.

3.

Inspect Connector Terminals.

a.

Visually inspect each terminal in connector. Verify terminals are not damaged. Verify terminals are properly

aligned in connector and verify terminals are properly located in connector.

b.

Expected Result. The terminals are properly aligned and terminals appear undamaged.

(1)

If terminals are OK, go to step 4.

(2)

If terminals of connector are damaged, repair terminals and/or replace terminals, as required. Verify repair

eliminates problem.

4.

Perform a Pull Test on Each Wire Terminal Connection.

a.

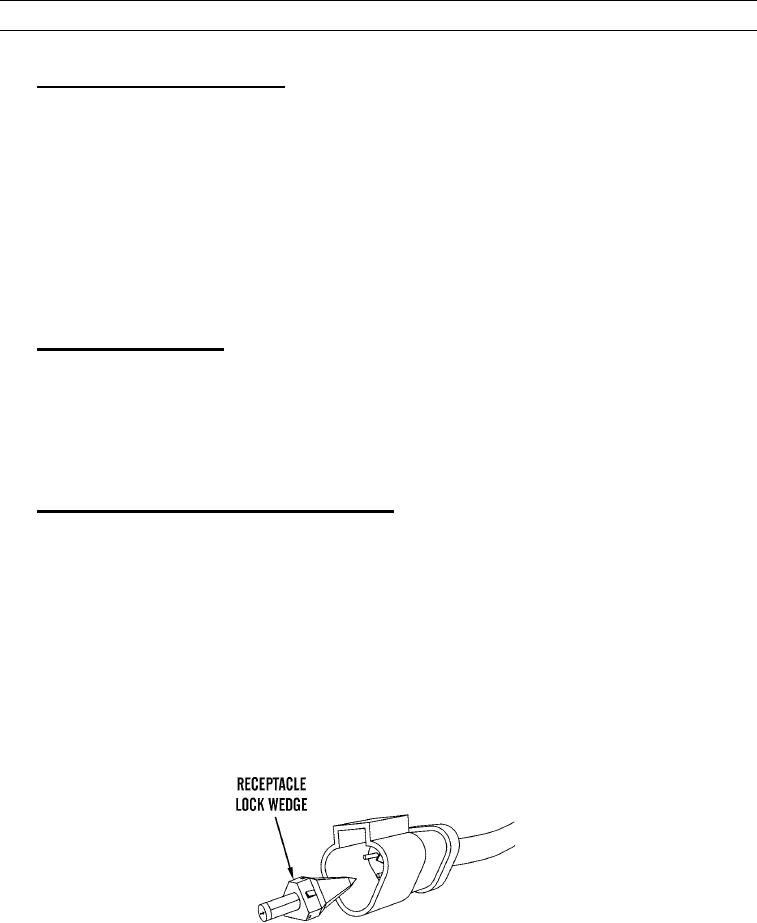

Ensure locking wedge for connector is installed properly. Terminals cannot be retained inside connector if locking

wedge is not installed properly.

b.

Perform the 10 lb (45 N) pull test on each wire. Each terminal and each connector should easily withstand 10 lb (45

N) of tension and each wire should remain in the connector body. This test checks whether wire was properly

crimped in terminal and whether terminal was properly inserted into connector.

c.

Expected Result. Each terminal and each connector easily withstands 10 lb (45 N) of pull and each wire remains

in connector body.

(1)

If all terminals pass the pull test, go to step 5.

(2)

If a wire has been pulled from a terminal or a terminal has been pulled from connector, use the crimping

tool to replace terminal. Replace damaged connectors, as required. Verify repair eliminates the problem.

427-C2046

0022 00-14