TM 5-3805-291-23-1

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

ELECTRICAL CONNECTORS INSPECTION (ENGINE) - CONTINUED

6.

Check Locking Mechanism of Connectors.

a.

Ensure connectors lock properly. After locking connectors, ensure two halves cannot be pulled apart.

b.

Verify latch tab of connector is properly latched. Also verify latch tab of connector returns to locked position.

c.

Expected Result. Connector will securely lock. Connector and locking mechanism are without cracks or breaks.

(1)

If connectors are in good repair, go to step 7.

(2)

If connector's locking mechanism is damaged or missing, repair connector or replace connector, as

required. Verify repair eliminates problem.

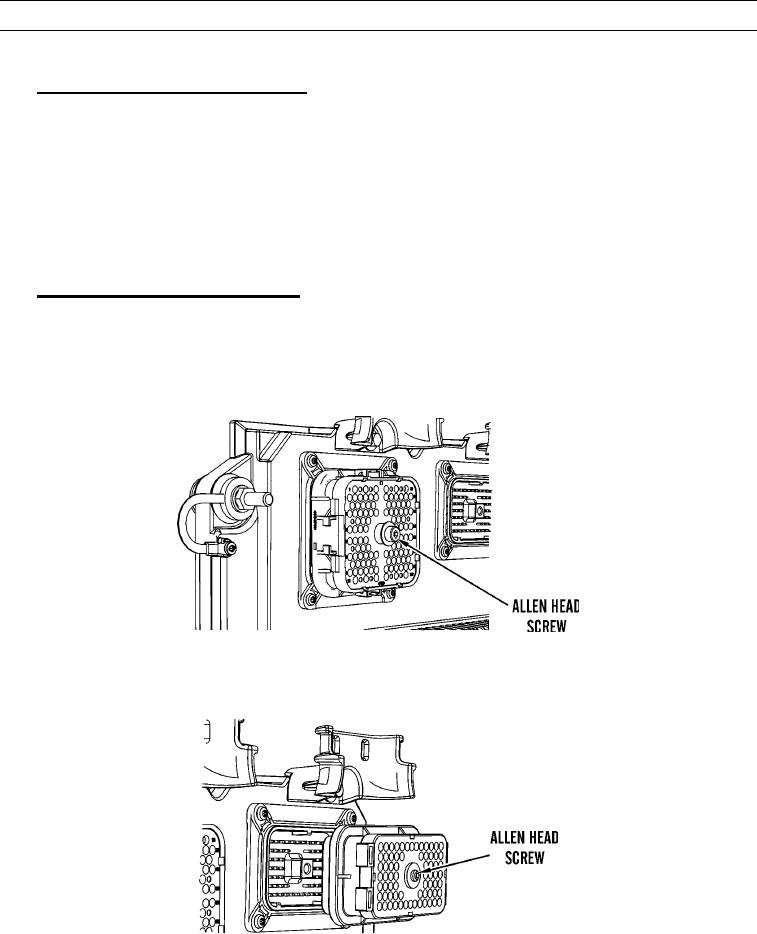

7.

Check Allen Head Screws on Connectors.

a.

Visually inspect allen head screws for ECM connectors. Ensure threads on each allen head screw are not damaged.

Connect ECM connectors.

(1)

Torque allen head bolt for the 120-pin ECM connector to 60 4 lb-in. (7.0 0.5 Nm).

427-C2048

(2)

Torque allen head screw for 70-pin ECM connector to 55 13 - 4 lb-in. (6.0 1.5 - 0.5 Nm).

427-C2049

0022 00-16