TM 5-3805-291-23-1

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

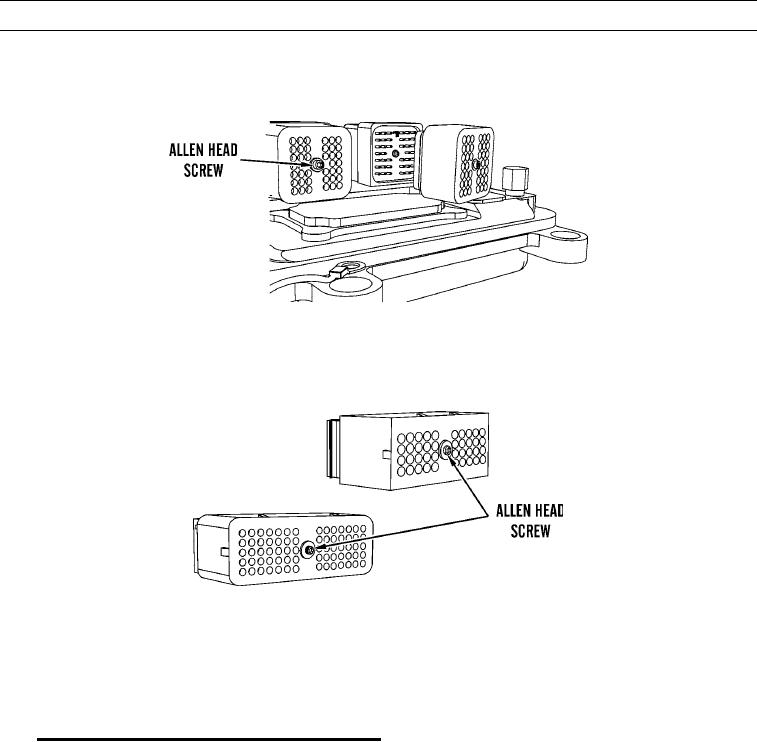

ELECTRICAL CONNECTORS INSPECTION (ENGINE) - CONTINUED

(3)

Torque allen head screw for 40-pin ECM connector to 20 2 lb-in. (2.25 0.25 Nm).

427-C2050

b.

Connect machine interface connector (MIC). Torque allen head screw for 40-pin MIC and 70-pin MIC to 20 2

lb-in. (2.25 0.25 Nm).

427-C2051

c.

Expected Result. ECM connector is secure and allen head screws are properly torqued.

(1)

If ECM connectors and customer connector is properly connected, go to step 8.

(2)

If allen head screws for ECM connector or customer connector is damaged, repair connector or replace

connector, as required. Verify repair eliminates problem.

8.

Perform "Wiggle Test" on Electronic Technician (ET).

a.

Select "Wiggle Test" from diagnostic tests on ET.

b.

Choose appropriate group of parameters to monitor.

c.

Press "Start" button. Wiggle wiring harness in order to reproduce intermittent problems.

If an intermittent problem exists, the status will be highlighted and an audible beep will be heard.

d.

Expected Result. No intermittent problems were indicated during "Wiggle Test".

(1)

If no intermittent problems were found, harness and connectors appear to be OK. If you were sent from

another procedure, return to procedure and continue testing. If this test has resolved problem, return engine

to service.

(2)

If at least one intermittent problem was indicated, repair harness or connector. Verify repair eliminates

problem.

0022 00-17