TM 5-3805-291-23-1

ELECTRICAL GENERAL MAINTENANCE INSTRUCTIONS - CONTINUED

0022 00

ELECTRICAL CONNECTOR INSPECTION (POWERTRAIN)

0022 00

1.

Background Information.

N OT E

a.

Use this procedure to help determine if connector is the cause of the problem. If a problem is

found in electrical connector, repair connector and verify problem has been corrected.

b.

Many of the operational procedures and diagnostic code procedures in this troubleshooting

guide will instruct you to check a specific electrical connector.

c.

Intermittent electrical problems are often caused by poor connections. Always check for an

active diagnostic code before breaking any connections. Also, always check for an active

diagnostic code after connector is reconnected in order to verify problem disappears.

d.

Simply disconnecting connectors and then reconnecting the connectors can temporarily solve

a problem at times. If this occurs, likely causes are loose terminals, bent terminals, improperly

crimped terminals, corrosion, or harness routing is improper.

e.

The original source of the problem must then be identified in order to ensure problem does

not recur.

f.

Follow this procedure to thoroughly inspect connectors in order to determine if connectors

are the cause of the problem.

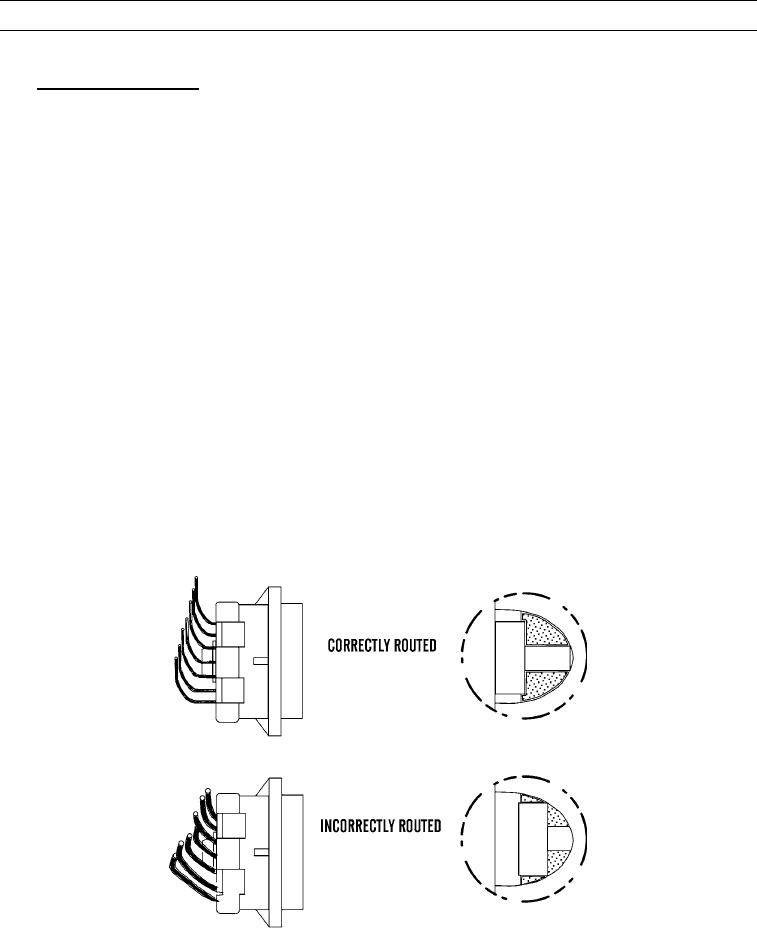

(1) Correctly Routed Harness

(2) Correctly Inserted Plug

(3) Incorrectly Routed Harness

(4) Incorrectly Inserted Plug

427-C2052

0022 00-18